Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

8.2.3 Fillers<br />

Using <strong>WEST</strong> <strong>SYSTEM</strong> <strong>Epoxy</strong> 58<br />

Throughout this manual, we will refer to epoxy or resin/hardener mixture, meaning<br />

mixed resin and hardener without fillers added; and thickened mixture or thickened<br />

epoxy, meaning resin/hardener with one of six fillers added. With the exception of<br />

G/flex 655 and Six10 Adhesive, fillers are used to thicken the epoxy for specific applications.<br />

They are categorized as either Adhesive Fillers—used for structural bonding<br />

or gluing, and gap-filling; or Fairing Fillers—used for cosmetic surface filling.<br />

Adhesive fillers<br />

403 Microfibers—For general bonding and gap filling. <strong>Epoxy</strong>/403 mixtures have superior<br />

gap-filling qualities and good strength for most bonding applications while retaining<br />

wetting/penetrating capabilities. Works especially well with porous woods.<br />

Cures to an off-white color.<br />

404 High-Density Filler—For hardware fastener bonding and applications that require<br />

maximum physical properties and where high-cyclic loads are anticipated. Also<br />

used for gap-filling where maximum strength is necessary. Cures to an off-white color.<br />

405 Filleting Blend—For use in bonding and filleting on naturally finished wood projects.<br />

A strong, wood-toned filler that mixes easily and spreads smoothly. Cures to a<br />

brown color and can be used to tint other fillers.<br />

406 Colloidal Silica—For general bonding, gap-filling, high-strength bonds and fillets.<br />

A practical and versatile, smooth-textured filler. It can be used alone or mixed with<br />

other fillers to improve workability and smoothness. Cures to an off-white color.<br />

Fairing fillers<br />

407 Low-Density Filler—A blended microballoon-based filler used to make a fairing<br />

compound that is easy to sand or carve while still being reasonably strong on a<br />

strength-to-weight basis. Cures to a reddish-brown color.<br />

410 Microlight ® —A very low-density filler for creating a light, easily-worked fairing<br />

compound. 410 spreads smoothly and sands very easily when cured. Not recommended<br />

under dark colored paint or on other surfaces subject to high temperatures.<br />

Cures to a light tan color.<br />

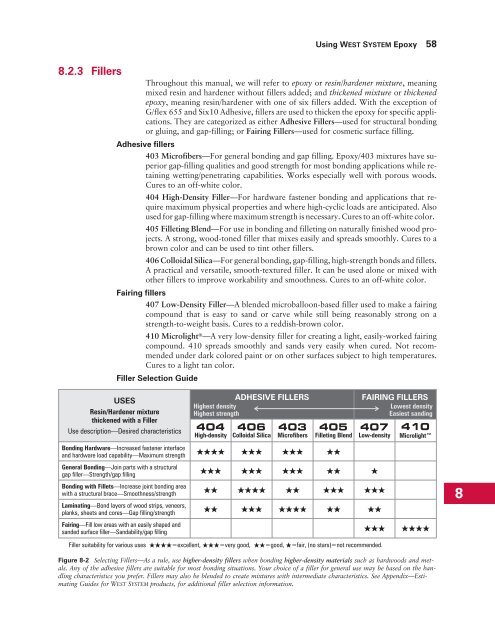

Filler Selection Guide<br />

USES<br />

Resin/Hardener mixture<br />

thickened with a Filler<br />

Use description—Desired characteristics<br />

Bonding Hardware—Increased fastener interface<br />

and hardware load capability—Maximum strength<br />

Highest density<br />

Highest strength<br />

404<br />

High-density<br />

ADHESIVE FILLERS FAIRING FILLERS<br />

406<br />

Colloidal Silica<br />

403<br />

Microfibers<br />

405<br />

Filleting Blend<br />

<br />

407<br />

Low-density<br />

General Bonding—Join parts with a structural<br />

gap filler—Strength/gap filling <br />

Bonding with Fillets—Increase joint bonding area<br />

with a structural brace—Smoothness/strength <br />

Laminating—Bond layers of wood strips, veneers,<br />

planks, sheets and cores—Gap filling/strength <br />

Lowest density<br />

Easiest sanding<br />

410<br />

Microlight<br />

Fairing—Fill low areas with an easily shaped and<br />

sanded surface filler—Sandability/gap filling <br />

Filler suitability for various uses =excellent, =very good, =good, =fair, (no stars)=not recommended.<br />

Figure 8-2 Selecting Fillers—As a rule, use higher-density fillers when bonding higher-density materials such as hardwoods and metals.<br />

Any of the adhesive fillers are suitable for most bonding situations. Your choice of a filler for general use may be based on the handling<br />

characteristics you prefer. Fillers may also be blended to create mixtures with intermediate characteristics. See Appendix—Estimating<br />

Guides for <strong>WEST</strong> <strong>SYSTEM</strong> products, for additional filler selection information.<br />

8