Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

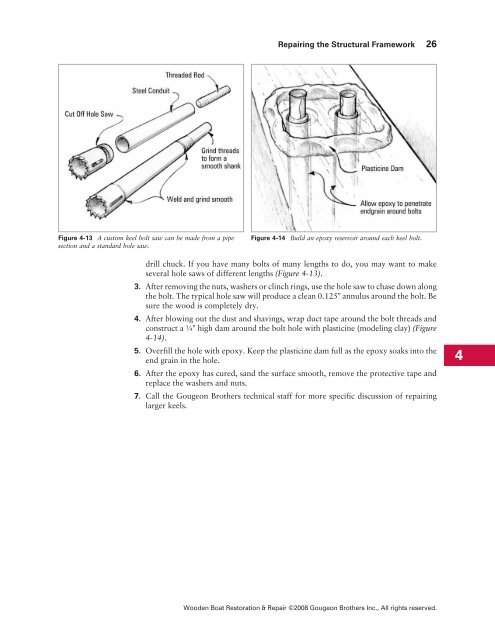

Figure 4-13 A custom keel bolt saw can be made from a pipe<br />

section and a standard hole saw.<br />

<strong>Repair</strong>ing the Structural Framework 26<br />

Figure 4-14 Build an epoxy reservoir around each keel bolt.<br />

drill chuck. If you have many bolts of many lengths to do, you may want to make<br />

several hole saws of different lengths (Figure 4-13).<br />

3. After removing the nuts, washers or clinch rings, use the hole saw to chase down along<br />

the bolt. The typical hole saw will produce a clean 0.125" annulus around the bolt. Be<br />

sure the wood is completely dry.<br />

4. After blowing out the dust and shavings, wrap duct tape around the bolt threads and<br />

construct a ¼" high dam around the bolt hole with plasticine (modeling clay) (Figure<br />

4-14).<br />

5. Overfill the hole with epoxy. Keep the plasticine dam full as the epoxy soaks into the<br />

end grain in the hole.<br />

6. After the epoxy has cured, sand the surface smooth, remove the protective tape and<br />

replace the washers and nuts.<br />

7. Call the Gougeon Brothers technical staff for more specific discussion of repairing<br />

larger keels.<br />

<strong>Wooden</strong> <strong>Boat</strong> <strong>Restoration</strong> & <strong>Repair</strong> ©2008 Gougeon Brothers Inc., All rights reserved.<br />

4