Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

206 Slow Hardener ® —Used for general bonding, barrier coating and fabric application.<br />

Formulated for a longer working and cure time or to provide adequate working<br />

time at higher temperatures. 5:1 mix ratio.<br />

Note: 205 Fast and 206 Slow Hardener may be blended for intermediate cure times.<br />

Always maintain the proper 5 part resin to 1 part hardener ratio. Do not mix 205 or<br />

206 (5-to-1 ratio) Hardeners with 207 or 209 (3-to-1 ratio) Hardeners.<br />

209 Extra Slow Hardener— Used for general bonding, barrier coating and fabric application<br />

in extremely warm and/or humid conditions. Provides approximately twice<br />

the pot life and working time as 206 Slow Hardener and adequate pot life up to 110°F<br />

(43°C). Also used at room temperatures when a long pot life and working time are<br />

required. 3:1 mix ratio.<br />

207 Special Clear Hardener—Formulated specifically for barrier coating and fabric<br />

application where clear finish is desired. 207 has a low-viscosity for good fabric wet<br />

out. 207 contains a UV stabilization additive, but still requires long term UV protection<br />

with paint or varnish. 207 provides a blush-free coating with good physical properties<br />

for bonding. 3:1 mix ratio.<br />

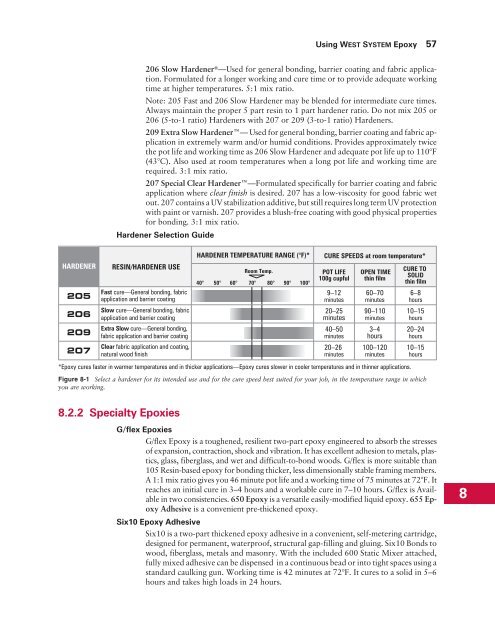

Hardener Selection Guide<br />

HARDENER RESIN/HARDENER USE<br />

205<br />

206<br />

209<br />

207<br />

Fast cure—General bonding, fabric<br />

application and barrier coating<br />

Slow cure—General bonding, fabric<br />

application and barrier coating<br />

Extra Slow cure—General bonding,<br />

fabric application and barrier coating<br />

Clear fabric application and coating,<br />

natural wood finish<br />

8.2.2 Specialty Epoxies<br />

Using <strong>WEST</strong> <strong>SYSTEM</strong> <strong>Epoxy</strong> 57<br />

HARDENER TEMPERATURE RANGE (°F)* CURE SPEEDS at room temperature*<br />

40° 50°<br />

Room Temp.<br />

60° 70° 80° 90° 100°<br />

POT LIFE<br />

100g cupful<br />

9–12<br />

minutes<br />

20–25<br />

minutes<br />

40–50<br />

minutes<br />

20–26<br />

minutes<br />

OPEN TIME<br />

thin film<br />

60–70<br />

minutes<br />

90–110<br />

minutes<br />

3–4<br />

hours<br />

100–120<br />

minutes<br />

CURE TO<br />

SOLID<br />

thin film<br />

6–8<br />

hours<br />

10–15<br />

hours<br />

20–24<br />

hours<br />

10–15<br />

hours<br />

*<strong>Epoxy</strong> cures faster in warmer temperatures and in thicker applications—<strong>Epoxy</strong> cures slower in cooler temperatures and in thinner applications.<br />

Figure 8-1 Select a hardener for its intended use and for the cure speed best suited for your job, in the temperature range in which<br />

you are working.<br />

G/flex Epoxies<br />

G/flex <strong>Epoxy</strong> is a toughened, resilient two-part epoxy engineered to absorb the stresses<br />

of expansion, contraction, shock and vibration. It has excellent adhesion to metals, plastics,<br />

glass, fiberglass, and wet and difficult-to-bond woods. G/flex is more suitable than<br />

105 Resin-based epoxy for bonding thicker, less dimensionally stable framing members.<br />

A 1:1 mix ratio gives you 46 minute pot life and a working time of 75 minutes at 72°F. It<br />

reaches an initial cure in 3–4 hours and a workable cure in 7–10 hours. G/flex is Available<br />

in two consistencies. 650 <strong>Epoxy</strong> is a versatile easily-modified liquid epoxy. 655 <strong>Epoxy</strong><br />

Adhesive is a convenient pre-thickened epoxy.<br />

Six10 <strong>Epoxy</strong> Adhesive<br />

Six10 is a two-part thickened epoxy adhesive in a convenient, self-metering cartridge,<br />

designed for permanent, waterproof, structural gap-filling and gluing. Six10 Bonds to<br />

wood, fiberglass, metals and masonry. With the included 600 Static Mixer attached,<br />

fully mixed adhesive can be dispensed in a continuous bead or into tight spaces using a<br />

standard caulking gun. Working time is 42 minutes at 72°F. It cures to a solid in 5–6<br />

hours and takes high loads in 24 hours.<br />

8