Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

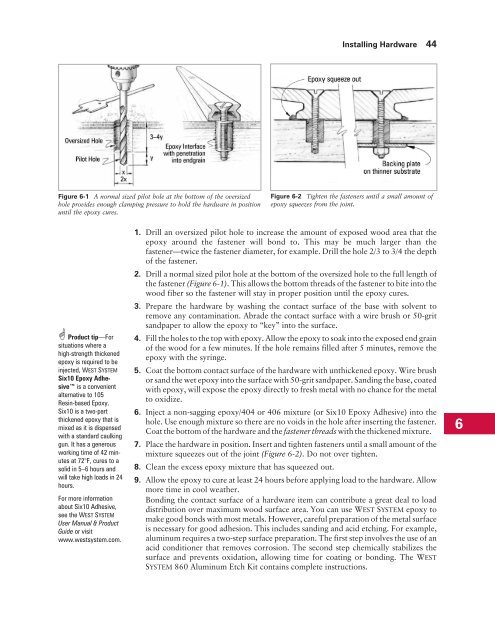

Figure 6-1 A normal sized pilot hole at the bottom of the oversized<br />

hole provides enough clamping pressure to hold the hardware in position<br />

until the epoxy cures.<br />

Product tip—For<br />

situations where a<br />

high-strength thickened<br />

epoxy is required to be<br />

injected, <strong>WEST</strong> <strong>SYSTEM</strong><br />

Six10 <strong>Epoxy</strong> Adhesive<br />

is a convenient<br />

alternative to 105<br />

Resin-based <strong>Epoxy</strong>.<br />

Six10 is a two-part<br />

thickened epoxy that is<br />

mixed as it is dispensed<br />

with a standard caulking<br />

gun. It has a generous<br />

working time of 42 minutes<br />

at 72°F, cures to a<br />

solid in 5–6 hours and<br />

will take high loads in 24<br />

hours.<br />

For more information<br />

about Six10 Adhesive,<br />

see the <strong>WEST</strong> <strong>SYSTEM</strong><br />

User Manual & Product<br />

Guide or visit<br />

www.westsystem.com.<br />

Installing Hardware 44<br />

Figure 6-2 Tighten the fasteners until a small amount of<br />

epoxy squeezes from the joint.<br />

1. Drill an oversized pilot hole to increase the amount of exposed wood area that the<br />

epoxy around the fastener will bond to. This may be much larger than the<br />

fastener—twice the fastener diameter, for example. Drill the hole 2/3 to 3/4 the depth<br />

of the fastener.<br />

2. Drill a normal sized pilot hole at the bottom of the oversized hole to the full length of<br />

the fastener (Figure 6-1). This allows the bottom threads of the fastener to bite into the<br />

wood fiber so the fastener will stay in proper position until the epoxy cures.<br />

3. Prepare the hardware by washing the contact surface of the base with solvent to<br />

remove any contamination. Abrade the contact surface with a wire brush or 50-grit<br />

sandpaper to allow the epoxy to “key” into the surface.<br />

4. Fill the holes to the top with epoxy. Allow the epoxy to soak into the exposed end grain<br />

of the wood for a few minutes. If the hole remains filled after 5 minutes, remove the<br />

epoxy with the syringe.<br />

5. Coat the bottom contact surface of the hardware with unthickened epoxy. Wire brush<br />

or sand the wet epoxy into the surface with 50-grit sandpaper. Sanding the base, coated<br />

with epoxy, will expose the epoxy directly to fresh metal with no chance for the metal<br />

to oxidize.<br />

6. Inject a non-sagging epoxy/404 or 406 mixture (or Six10 <strong>Epoxy</strong> Adhesive) into the<br />

hole. Use enough mixture so there are no voids in the hole after inserting the fastener.<br />

Coat the bottom of the hardware and the fastener threads with the thickened mixture.<br />

7. Place the hardware in position. Insert and tighten fasteners until a small amount of the<br />

mixture squeezes out of the joint (Figure 6-2). Do not over tighten.<br />

8. Clean the excess epoxy mixture that has squeezed out.<br />

9. Allow the epoxy to cure at least 24 hours before applying load to the hardware. Allow<br />

more time in cool weather.<br />

Bonding the contact surface of a hardware item can contribute a great deal to load<br />

distribution over maximum wood surface area. You can use <strong>WEST</strong> <strong>SYSTEM</strong> epoxy to<br />

make good bonds with most metals. However, careful preparation of the metal surface<br />

is necessary for good adhesion. This includes sanding and acid etching. For example,<br />

aluminum requires a two-step surface preparation. The first step involves the use of an<br />

acid conditioner that removes corrosion. The second step chemically stabilizes the<br />

surface and prevents oxidation, allowing time for coating or bonding. The <strong>WEST</strong><br />

<strong>SYSTEM</strong> 860 Aluminum Etch Kit contains complete instructions.<br />

6