Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

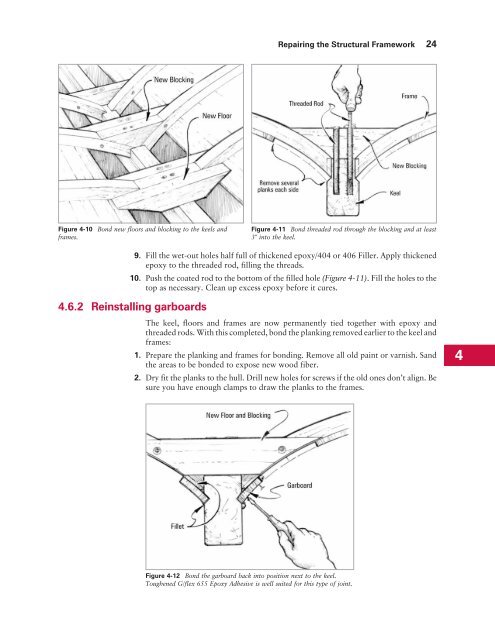

Figure 4-10 Bond new floors and blocking to the keels and<br />

frames.<br />

9. Fill the wet-out holes half full of thickened epoxy/404 or 406 Filler. Apply thickened<br />

epoxy to the threaded rod, filling the threads.<br />

10. Push the coated rod to the bottom of the filled hole (Figure 4-11). Fill the holes to the<br />

top as necessary. Clean up excess epoxy before it cures.<br />

4.6.2 Reinstalling garboards<br />

<strong>Repair</strong>ing the Structural Framework 24<br />

Figure 4-11 Bond threaded rod through the blocking and at least<br />

3" into the keel.<br />

The keel, floors and frames are now permanently tied together with epoxy and<br />

threaded rods. With this completed, bond the planking removed earlier to the keel and<br />

frames:<br />

1. Prepare the planking and frames for bonding. Remove all old paint or varnish. Sand<br />

the areas to be bonded to expose new wood fiber.<br />

2. Dry fit the planks to the hull. Drill new holes for screws if the old ones don’t align. Be<br />

sure you have enough clamps to draw the planks to the frames.<br />

Figure 4-12 Bond the garboard back into position next to the keel.<br />

Toughened G/flex 655 <strong>Epoxy</strong> Adhesive is well suited for this type of joint.<br />

4