Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

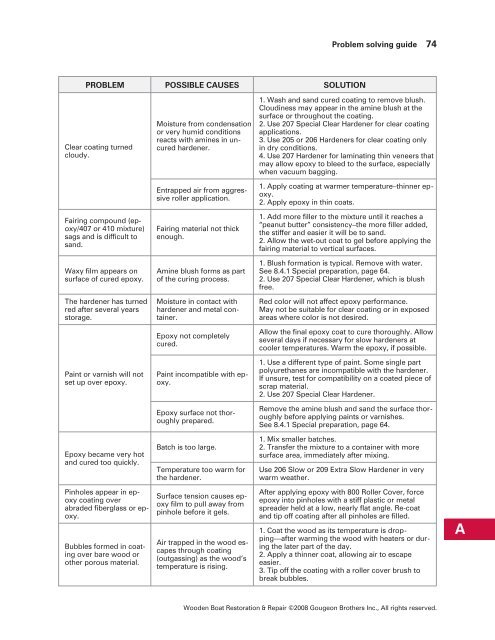

PROBLEM POSSIBLE CAUSES SOLUTION<br />

Clear coating turned<br />

cloudy.<br />

Fairing compound (epoxy/407<br />

or 410 mixture)<br />

sags and is difficult to<br />

sand.<br />

Waxy film appears on<br />

surface of cured epoxy.<br />

The hardener has turned<br />

red after several years<br />

storage.<br />

Paint or varnish will not<br />

set up over epoxy.<br />

<strong>Epoxy</strong> became very hot<br />

and cured too quickly.<br />

Pinholes appear in epoxy<br />

coating over<br />

abraded fiberglass or epoxy.<br />

Bubbles formed in coating<br />

over bare wood or<br />

other porous material.<br />

Moisture from condensation<br />

or very humid conditions<br />

reacts with amines in uncured<br />

hardener.<br />

Entrapped air from aggressive<br />

roller application.<br />

Fairing material not thick<br />

enough.<br />

Amine blush forms as part<br />

of the curing process.<br />

Moisture in contact with<br />

hardener and metal container.<br />

<strong>Epoxy</strong> not completely<br />

cured.<br />

Paint incompatible with epoxy.<br />

<strong>Epoxy</strong> surface not thoroughly<br />

prepared.<br />

Batch is too large.<br />

Temperature too warm for<br />

the hardener.<br />

Surface tension causes epoxy<br />

film to pull away from<br />

pinhole before it gels.<br />

Air trapped in the wood escapes<br />

through coating<br />

(outgassing) as the wood’s<br />

temperature is rising.<br />

Problem solving guide 74<br />

1. Wash and sand cured coating to remove blush.<br />

Cloudiness may appear in the amine blush at the<br />

surface or throughout the coating.<br />

2. Use 207 Special Clear Hardener for clear coating<br />

applications.<br />

3. Use 205 or 206 Hardeners for clear coating only<br />

in dry conditions.<br />

4. Use 207 Hardener for laminating thin veneers that<br />

may allow epoxy to bleed to the surface, especially<br />

when vacuum bagging.<br />

1. Apply coating at warmer temperature–thinner epoxy.<br />

2. Apply epoxy in thin coats.<br />

1. Add more filler to the mixture until it reaches a<br />

“peanut butter” consistency–the more filler added,<br />

the stiffer and easier it will be to sand.<br />

2. Allow the wet-out coat to gel before applying the<br />

fairing material to vertical surfaces.<br />

1. Blush formation is typical. Remove with water.<br />

See 8.4.1 Special preparation, page 64.<br />

2. Use 207 Special Clear Hardener, which is blush<br />

free.<br />

Red color will not affect epoxy performance.<br />

May not be suitable for clear coating or in exposed<br />

areas where color is not desired.<br />

Allow the final epoxy coat to cure thoroughly. Allow<br />

several days if necessary for slow hardeners at<br />

cooler temperatures. Warm the epoxy, if possible.<br />

1. Use a different type of paint. Some single part<br />

polyurethanes are incompatible with the hardener.<br />

If unsure, test for compatibility on a coated piece of<br />

scrap material.<br />

2. Use 207 Special Clear Hardener.<br />

Remove the amine blush and sand the surface thoroughly<br />

before applying paints or varnishes.<br />

See 8.4.1 Special preparation, page 64.<br />

1. Mix smaller batches.<br />

2. Transfer the mixture to a container with more<br />

surface area, immediately after mixing.<br />

Use 206 Slow or 209 Extra Slow Hardener in very<br />

warm weather.<br />

After applying epoxy with 800 Roller Cover, force<br />

epoxy into pinholes with a stiff plastic or metal<br />

spreader held at a low, nearly flat angle. Re-coat<br />

and tip off coating after all pinholes are filled.<br />

1. Coat the wood as its temperature is dropping—after<br />

warming the wood with heaters or during<br />

the later part of the day.<br />

2. Apply a thinner coat, allowing air to escape<br />

easier.<br />

3. Tip off the coating with a roller cover brush to<br />

break bubbles.<br />

<strong>Wooden</strong> <strong>Boat</strong> <strong>Restoration</strong> & <strong>Repair</strong> ©2008 Gougeon Brothers Inc., All rights reserved.<br />

A