Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

5.1.1 Cleaning out the seams<br />

Getting a good clean bonding surface on each plank edge is the first step. You can use a<br />

circular saw, a router, a chisel and hammer, or a sharpened scraper to clean all the old<br />

caulking material out of the joint and expose clean fresh wood for bonding on the<br />

facing edge of each plank. One tool may work better than another in a given situation,<br />

but a circular saw is usually the most effective way to mill out the seam accurately.<br />

1. Dry the hull thoroughly before beginning. This allows the seams to open to their<br />

widest and stabilizes the size and shape of all the pieces.<br />

2. Tack a batten to the hull to act as a guide for the saw. The batten should be parallel to<br />

the seam so the blade will follow the center of each seam exactly.<br />

3. Select a blade or reset the blade’s teeth wide enough to shave the edges of both planks<br />

facing the seam. Use a pair of pliers to bend the teeth for more set. The seam width may<br />

vary, but the cut should be at least 3 16" If the seams have opened very wide after drying,<br />

two passes with the saw may be necessary to shave both planks.<br />

4. Set the depth of the cut to 1 16" less than the thickness of the plank. Leave just enough<br />

material at the back of the seam to prevent epoxy from passing through to the inside.<br />

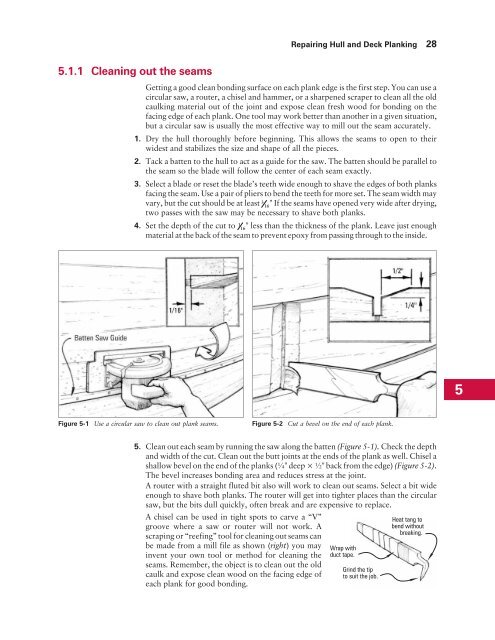

5. Clean out each seam by running the saw along the batten (Figure 5-1). Check the depth<br />

and width of the cut. Clean out the butt joints at the ends of the plank as well. Chisel a<br />

shallow bevel on the end of the planks (¼" deep × ½" back from the edge) (Figure 5-2).<br />

The bevel increases bonding area and reduces stress at the joint.<br />

A router with a straight fluted bit also will work to clean out seams. Select a bit wide<br />

enough to shave both planks. The router will get into tighter places than the circular<br />

saw, but the bits dull quickly, often break and are expensive to replace.<br />

A chisel can be used in tight spots to carve a “V”<br />

groove where a saw or router will not work. A<br />

scraping or “reefing” tool for cleaning out seams can<br />

be made from a mill file as shown (right) you may<br />

invent your own tool or method for cleaning the<br />

seams. Remember, the object is to clean out the old<br />

caulk and expose clean wood on the facing edge of<br />

each plank for good bonding.<br />

<strong>Repair</strong>ing Hull and Deck Planking 28<br />

Figure 5-1 Use a circular saw to clean out plank seams. Figure 5-2 Cut a bevel on the end of each plank.<br />

Wrap with<br />

duct tape.<br />

Grind the tip<br />

to suit the job.<br />

Heat tang to<br />

bend without<br />

breaking.<br />

5