Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

Wooden Boat Restoration Repair - WEST SYSTEM Epoxy

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

4.5 Joint repairs<br />

If the framing is not damaged from rot or impact, you may still want to bond the<br />

framing together to stiffen the structure and seal the joints against moisture. Remove as<br />

many frames as you can and bond them in place using the standard bonding techniques<br />

in Section 8.4.2. Many of the frames that can’t be removed can still be bonded into<br />

place as follows:<br />

1. Support the boat in its proper shape before bonding any joints.<br />

2. Open as many of the joints as you can reach, between frames and between frames and<br />

the outer skin. Loosen fasteners wherever possible. A small pry bar or wedge may be<br />

used to force the joint open temporarily. Use a saw blade or other sharp tool to scrape<br />

out old paint, varnish or dirt from the joints (Figure 4-7). Clean the inner joint surfaces<br />

to bare wood as much as possible.<br />

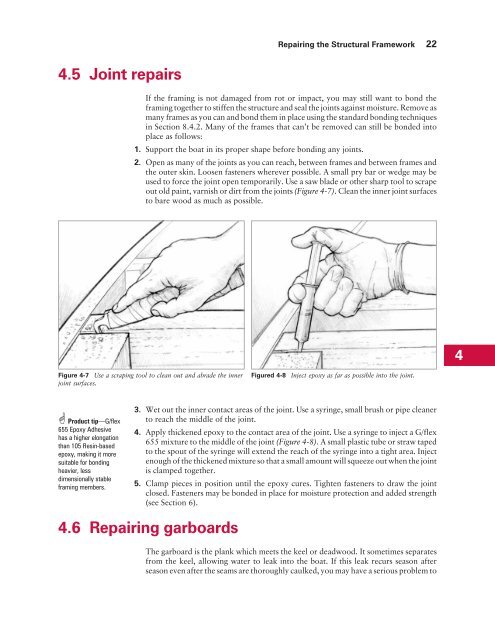

Figure 4-7 Use a scraping tool to clean out and abrade the inner<br />

joint surfaces.<br />

Product tip—G/flex<br />

655 <strong>Epoxy</strong> Adhesive<br />

has a higher elongation<br />

than 105 Resin-based<br />

epoxy, making it more<br />

suitable for bonding<br />

heavier, less<br />

dimensionally stable<br />

framing members.<br />

3. Wet out the inner contact areas of the joint. Use a syringe, small brush or pipe cleaner<br />

to reach the middle of the joint.<br />

4. Apply thickened epoxy to the contact area of the joint. Use a syringe to inject a G/flex<br />

655 mixture to the middle of the joint (Figure 4-8). A small plastic tube or straw taped<br />

to the spout of the syringe will extend the reach of the syringe into a tight area. Inject<br />

enough of the thickened mixture so that a small amount will squeeze out when the joint<br />

is clamped together.<br />

5. Clamp pieces in position until the epoxy cures. Tighten fasteners to draw the joint<br />

closed. Fasteners may be bonded in place for moisture protection and added strength<br />

(see Section 6).<br />

4.6 <strong>Repair</strong>ing garboards<br />

<strong>Repair</strong>ing the Structural Framework 22<br />

Figured 4-8 Inject epoxy as far as possible into the joint.<br />

The garboard is the plank which meets the keel or deadwood. It sometimes separates<br />

from the keel, allowing water to leak into the boat. If this leak recurs season after<br />

season even after the seams are thoroughly caulked, you may have a serious problem to<br />

4