User's Manual ISO TNC 360 (260020xx, 280490xx) - heidenhain

User's Manual ISO TNC 360 (260020xx, 280490xx) - heidenhain

User's Manual ISO TNC 360 (260020xx, 280490xx) - heidenhain

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

1 Introduction<br />

1.2 Fundamentals of NC<br />

Absolute workpiece positions<br />

Each position on the workpiece is clearly defined by its absolute coordinates.<br />

Example: Absolute coordinates of the position ➀:<br />

X = 20 mm<br />

Y = 10 mm<br />

Z = 15 mm<br />

If you are drilling or milling a workpiece according to a workpiece drawing<br />

with absolute coordinates, you are moving the tool to the coordinates.<br />

Incremental workpiece positions<br />

A position can be referenced to the previous nominal position: i.e. the<br />

relative datum is always the last programmed position. Such coordinates<br />

are referred to as incremental coordinates (increment = growth), or also<br />

incremental or chain dimensions (since the positions are defined as a<br />

chain of dimensions). Incremental coordinates are designated with G91.<br />

Example: Incremental coordinates of the position ➂<br />

referenced to position ➁<br />

Absolute coordinates of the position ➁ :<br />

X = 10 mm<br />

Y = 5 mm<br />

Z = 20 mm<br />

Incremental coordinates of the position ➂ :<br />

IX = 10 mm<br />

IY = 10 mm<br />

IZ = –15 mm<br />

If you are drilling or milling a workpiece according to a workpiece drawing<br />

with incremental coordinates, you are moving the tool by the coordinates.<br />

An incremental position definition is therefore intended as an immediately<br />

relative definition. This is also the case when a position is defined by the<br />

distance-to-go to the target position (here the relative datum is located at<br />

the target position). The distance-to-go has a negative algebraic sign if the<br />

target position lies in the negative axis direction from the actual position.<br />

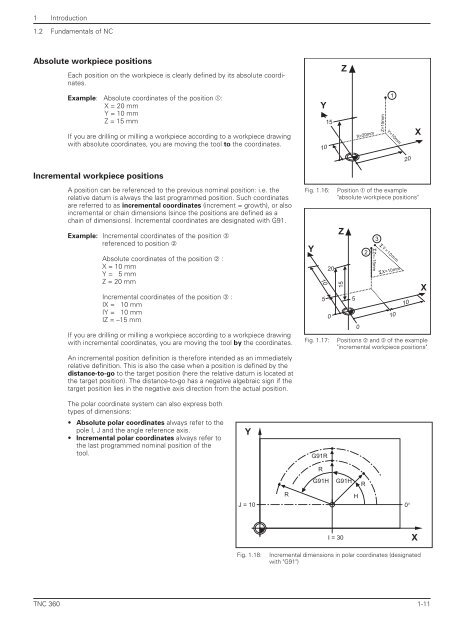

The polar coordinate system can also express both<br />

types of dimensions:<br />

• Absolute polar coordinates always refer to the<br />

pole I, J and the angle reference axis.<br />

• Incremental polar coordinates always refer to<br />

the last programmed nominal position of the<br />

tool.<br />

Fig. 1.16: Position ➀ of the example<br />

"absolute workpiece positions"<br />

Fig. 1.17: Positions ➁ and ➂ of the example<br />

"incremental workpiece positions"<br />

<strong>TNC</strong> <strong>360</strong> 1-11<br />

Y<br />

Y<br />

10 Z=15mm<br />

Y<br />

10<br />

5<br />

G91R<br />

R<br />

15<br />

20<br />

0<br />

Z<br />

Z<br />

15<br />

G91H G91H<br />

5<br />

1<br />

X=20mm Y=10mm<br />

0<br />

2<br />

3<br />

IZ=–15mm<br />

IY=10mm<br />

IX=10mm<br />

R<br />

H<br />

J = 10 0°<br />

I = 30<br />

Fig. 1.18: Incremental dimensions in polar coordinates (designated<br />

with "G91")<br />

R<br />

10<br />

20<br />

10<br />

X<br />

X<br />

X