Volume-II - GAIL

Volume-II - GAIL

Volume-II - GAIL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

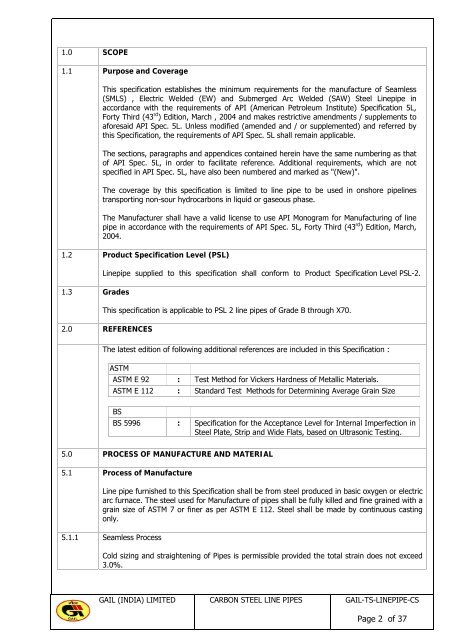

1.0 SCOPE<br />

1.1 Purpose and Coverage<br />

This specification establishes the minimum requirements for the manufacture of Seamless<br />

(SMLS) , Electric Welded (EW) and Submerged Arc Welded (SAW) Steel Linepipe in<br />

accordance with the requirements of API (American Petroleum Institute) Specification 5L,<br />

Forty Third (43 rd ) Edition, March , 2004 and makes restrictive amendments / supplements to<br />

aforesaid API Spec. 5L. Unless modified (amended and / or supplemented) and referred by<br />

this Specification, the requirements of API Spec. 5L shall remain applicable.<br />

The sections, paragraphs and appendices contained herein have the same numbering as that<br />

of API Spec. 5L, in order to facilitate reference. Additional requirements, which are not<br />

specified in API Spec. 5L, have also been numbered and marked as "(New)".<br />

The coverage by this specification is limited to line pipe to be used in onshore pipelines<br />

transporting non-sour hydrocarbons in liquid or gaseous phase.<br />

The Manufacturer shall have a valid license to use API Monogram for Manufacturing of line<br />

pipe in accordance with the requirements of API Spec. 5L, Forty Third (43 rd ) Edition, March,<br />

2004.<br />

1.2 Product Specification Level (PSL)<br />

1.3 Grades<br />

Linepipe supplied to this specification shall conform to Product Specification Level PSL-2.<br />

This specification is applicable to PSL 2 line pipes of Grade B through X70.<br />

2.0 REFERENCES<br />

The latest edition of following additional references are included in this Specification :<br />

ASTM<br />

ASTM E 92 : Test Method for Vickers Hardness of Metallic Materials.<br />

ASTM E 112 : Standard Test Methods for Determining Average Grain Size<br />

BS<br />

BS 5996 : Specification for the Acceptance Level for Internal Imperfection in<br />

Steel Plate, Strip and Wide Flats, based on Ultrasonic Testing.<br />

5.0 PROCESS OF MANUFACTURE AND MATERIAL<br />

5.1 Process of Manufacture<br />

Line pipe furnished to this Specification shall be from steel produced in basic oxygen or electric<br />

arc furnace. The steel used for Manufacture of pipes shall be fully killed and fine grained with a<br />

grain size of ASTM 7 or finer as per ASTM E 112. Steel shall be made by continuous casting<br />

only.<br />

5.1.1 Seamless Process<br />

Cold sizing and straightening of Pipes is permissible provided the total strain does not exceed<br />

3.0%.<br />

<strong>GAIL</strong> (INDIA) LIMITED CARBON STEEL LINE PIPES <strong>GAIL</strong>-TS-LINEPIPE-CS<br />

Page 2 of 37