Volume-II - GAIL

Volume-II - GAIL

Volume-II - GAIL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

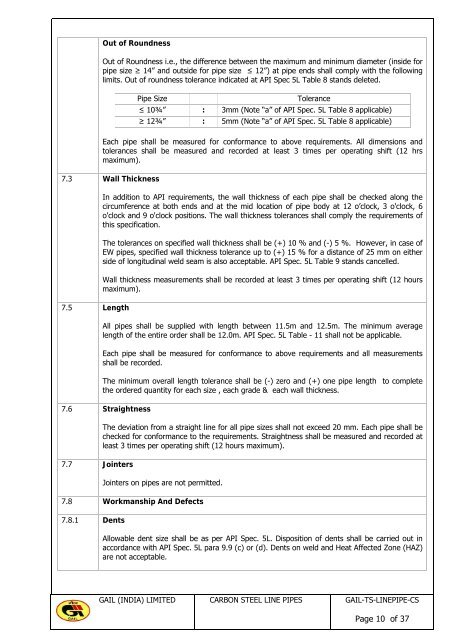

Out of Roundness<br />

Out of Roundness i.e., the difference between the maximum and minimum diameter (inside for<br />

pipe size ≥ 14” and outside for pipe size ≤ 12”) at pipe ends shall comply with the following<br />

limits. Out of roundness tolerance indicated at API Spec 5L Table 8 stands deleted.<br />

Pipe Size Tolerance<br />

≤ 10¾” : 3mm (Note “a” of API Spec. 5L Table 8 applicable)<br />

≥ 12¾” : 5mm (Note “a” of API Spec. 5L Table 8 applicable)<br />

Each pipe shall be measured for conformance to above requirements. All dimensions and<br />

tolerances shall be measured and recorded at least 3 times per operating shift (12 hrs<br />

maximum).<br />

7.3 Wall Thickness<br />

7.5 Length<br />

In addition to API requirements, the wall thickness of each pipe shall be checked along the<br />

circumference at both ends and at the mid location of pipe body at 12 o’clock, 3 o'clock, 6<br />

o'clock and 9 o'clock positions. The wall thickness tolerances shall comply the requirements of<br />

this specification.<br />

The tolerances on specified wall thickness shall be (+) 10 % and (-) 5 %. However, in case of<br />

EW pipes, specified wall thickness tolerance up to (+) 15 % for a distance of 25 mm on either<br />

side of longitudinal weld seam is also acceptable. API Spec. 5L Table 9 stands cancelled.<br />

Wall thickness measurements shall be recorded at least 3 times per operating shift (12 hours<br />

maximum).<br />

All pipes shall be supplied with length between 11.5m and 12.5m. The minimum average<br />

length of the entire order shall be 12.0m. API Spec. 5L Table - 11 shall not be applicable.<br />

Each pipe shall be measured for conformance to above requirements and all measurements<br />

shall be recorded.<br />

The minimum overall length tolerance shall be (-) zero and (+) one pipe length to complete<br />

the ordered quantity for each size , each grade & each wall thickness.<br />

7.6 Straightness<br />

7.7 Jointers<br />

The deviation from a straight line for all pipe sizes shall not exceed 20 mm. Each pipe shall be<br />

checked for conformance to the requirements. Straightness shall be measured and recorded at<br />

least 3 times per operating shift (12 hours maximum).<br />

Jointers on pipes are not permitted.<br />

7.8 Workmanship And Defects<br />

7.8.1 Dents<br />

Allowable dent size shall be as per API Spec. 5L. Disposition of dents shall be carried out in<br />

accordance with API Spec. 5L para 9.9 (c) or (d). Dents on weld and Heat Affected Zone (HAZ)<br />

are not acceptable.<br />

<strong>GAIL</strong> (INDIA) LIMITED CARBON STEEL LINE PIPES <strong>GAIL</strong>-TS-LINEPIPE-CS<br />

Page 10 of 37