Volume-II - GAIL

Volume-II - GAIL

Volume-II - GAIL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

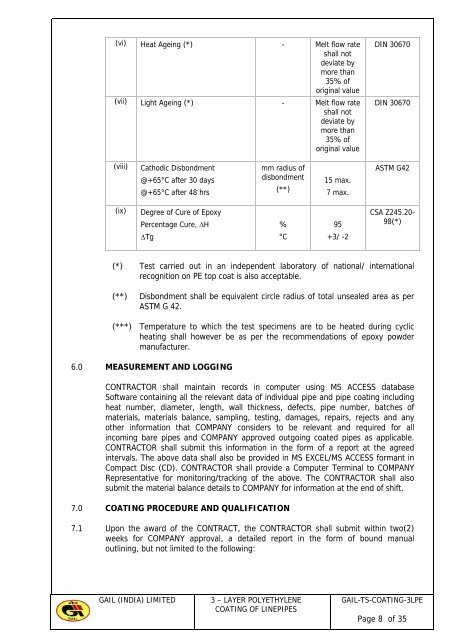

(vi) Heat Ageing (*) - Melt flow rate<br />

shall not<br />

deviate by<br />

more than<br />

35% of<br />

original value<br />

(vii) Light Ageing (*) - Melt flow rate<br />

shall not<br />

deviate by<br />

more than<br />

35% of<br />

original value<br />

(viii) Cathodic Disbondment<br />

@+65°C after 30 days<br />

@+65°C after 48 hrs<br />

(ix) Degree of Cure of Epoxy<br />

Percentage Cure, ∆H<br />

∆Tg<br />

mm radius of<br />

disbondment<br />

(**)<br />

%<br />

°C<br />

15 max.<br />

7 max.<br />

95<br />

+3/ -2<br />

DIN 30670<br />

DIN 30670<br />

ASTM G42<br />

CSA Z245.20-<br />

98(*)<br />

(*) Test carried out in an independent laboratory of national/ international<br />

recognition on PE top coat is also acceptable.<br />

(**) Disbondment shall be equivalent circle radius of total unsealed area as per<br />

ASTM G 42.<br />

(***) Temperature to which the test specimens are to be heated during cyclic<br />

heating shall however be as per the recommendations of epoxy powder<br />

manufacturer.<br />

6.0 MEASUREMENT AND LOGGING<br />

CONTRACTOR shall maintain records in computer using MS ACCESS database<br />

Software containing all the relevant data of individual pipe and pipe coating including<br />

heat number, diameter, length, wall thickness, defects, pipe number, batches of<br />

materials, materials balance, sampling, testing, damages, repairs, rejects and any<br />

other information that COMPANY considers to be relevant and required for all<br />

incoming bare pipes and COMPANY approved outgoing coated pipes as applicable.<br />

CONTRACTOR shall submit this information in the form of a report at the agreed<br />

intervals. The above data shall also be provided in MS EXCEL/MS ACCESS formant in<br />

Compact Disc (CD). CONTRACTOR shall provide a Computer Terminal to COMPANY<br />

Representative for monitoring/tracking of the above. The CONTRACTOR shall also<br />

submit the material balance details to COMPANY for information at the end of shift.<br />

7.0 COATING PROCEDURE AND QUALIFICATION<br />

7.1 Upon the award of the CONTRACT, the CONTRACTOR shall submit within two(2)<br />

weeks for COMPANY approval, a detailed report in the form of bound manual<br />

outlining, but not limited to the following:<br />

<strong>GAIL</strong> (INDIA) LIMITED<br />

3 – LAYER POLYETHYLENE<br />

COATING OF LINEPIPES<br />

<strong>GAIL</strong>-TS-COATING-3LPE<br />

Page 8 of 35