Volume-II - GAIL

Volume-II - GAIL

Volume-II - GAIL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

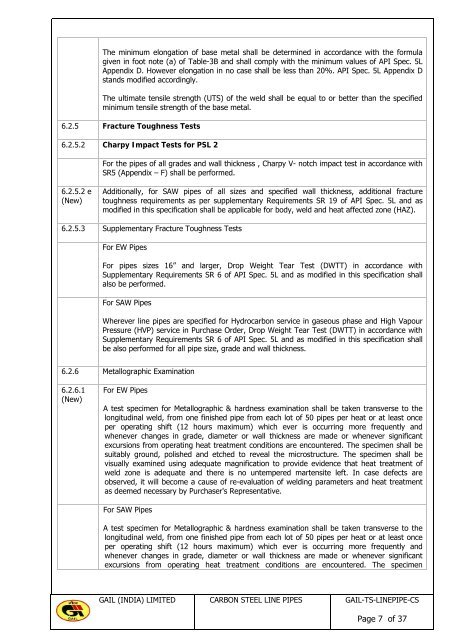

6.2.5<br />

The minimum elongation of base metal shall be determined in accordance with the formula<br />

given in foot note (a) of Table-3B and shall comply with the minimum values of API Spec. 5L<br />

Appendix D. However elongation in no case shall be less than 20%. API Spec. 5L Appendix D<br />

stands modified accordingly.<br />

The ultimate tensile strength (UTS) of the weld shall be equal to or better than the specified<br />

minimum tensile strength of the base metal.<br />

Fracture Toughness Tests<br />

6.2.5.2 Charpy Impact Tests for PSL 2<br />

6.2.5.2 e<br />

(New)<br />

For the pipes of all grades and wall thickness , Charpy V- notch impact test in accordance with<br />

SR5 (Appendix – F) shall be performed.<br />

Additionally, for SAW pipes of all sizes and specified wall thickness, additional fracture<br />

toughness requirements as per supplementary Requirements SR 19 of API Spec. 5L and as<br />

modified in this specification shall be applicable for body, weld and heat affected zone (HAZ).<br />

6.2.5.3 Supplementary Fracture Toughness Tests<br />

6.2.6<br />

6.2.6.1<br />

(New)<br />

For EW Pipes<br />

For pipes sizes 16” and larger, Drop Weight Tear Test (DWTT) in accordance with<br />

Supplementary Requirements SR 6 of API Spec. 5L and as modified in this specification shall<br />

also be performed.<br />

For SAW Pipes<br />

Wherever line pipes are specified for Hydrocarbon service in gaseous phase and High Vapour<br />

Pressure (HVP) service in Purchase Order, Drop Weight Tear Test (DWTT) in accordance with<br />

Supplementary Requirements SR 6 of API Spec. 5L and as modified in this specification shall<br />

be also performed for all pipe size, grade and wall thickness.<br />

Metallographic Examination<br />

For EW Pipes<br />

A test specimen for Metallographic & hardness examination shall be taken transverse to the<br />

longitudinal weld, from one finished pipe from each lot of 50 pipes per heat or at least once<br />

per operating shift (12 hours maximum) which ever is occurring more frequently and<br />

whenever changes in grade, diameter or wall thickness are made or whenever significant<br />

excursions from operating heat treatment conditions are encountered. The specimen shall be<br />

suitably ground, polished and etched to reveal the microstructure. The specimen shall be<br />

visually examined using adequate magnification to provide evidence that heat treatment of<br />

weld zone is adequate and there is no untempered martensite left. In case defects are<br />

observed, it will become a cause of re-evaluation of welding parameters and heat treatment<br />

as deemed necessary by Purchaser's Representative.<br />

For SAW Pipes<br />

A test specimen for Metallographic & hardness examination shall be taken transverse to the<br />

longitudinal weld, from one finished pipe from each lot of 50 pipes per heat or at least once<br />

per operating shift (12 hours maximum) which ever is occurring more frequently and<br />

whenever changes in grade, diameter or wall thickness are made or whenever significant<br />

excursions from operating heat treatment conditions are encountered. The specimen<br />

<strong>GAIL</strong> (INDIA) LIMITED CARBON STEEL LINE PIPES <strong>GAIL</strong>-TS-LINEPIPE-CS<br />

Page 7 of 37