Volume-II - GAIL

Volume-II - GAIL

Volume-II - GAIL

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6.2.6.2<br />

(New)<br />

6.2.7<br />

(New)<br />

6.2.7.1<br />

(New)<br />

6.2.7.2<br />

(New)<br />

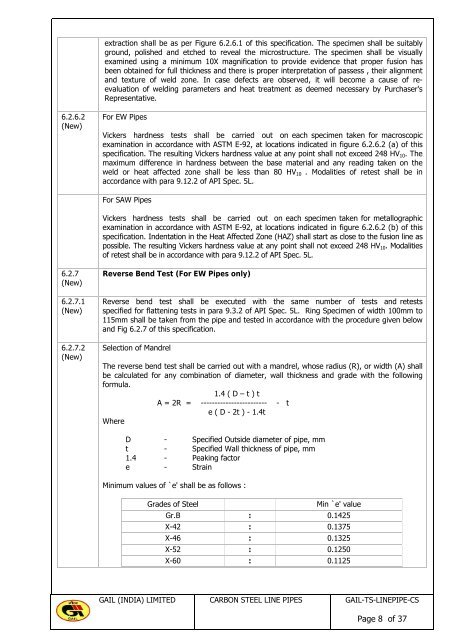

extraction shall be as per Figure 6.2.6.1 of this specification. The specimen shall be suitably<br />

ground, polished and etched to reveal the microstructure. The specimen shall be visually<br />

examined using a minimum 10X magnification to provide evidence that proper fusion has<br />

been obtained for full thickness and there is proper interpretation of passess , their alignment<br />

and texture of weld zone. In case defects are observed, it will become a cause of reevaluation<br />

of welding parameters and heat treatment as deemed necessary by Purchaser's<br />

Representative.<br />

For EW Pipes<br />

Vickers hardness tests shall be carried out on each specimen taken for macroscopic<br />

examination in accordance with ASTM E-92, at locations indicated in figure 6.2.6.2 (a) of this<br />

specification. The resulting Vickers hardness value at any point shall not exceed 248 HV10. The<br />

maximum difference in hardness between the base material and any reading taken on the<br />

weld or heat affected zone shall be less than 80 HV10 . Modalities of retest shall be in<br />

accordance with para 9.12.2 of API Spec. 5L.<br />

For SAW Pipes<br />

Vickers hardness tests shall be carried out on each specimen taken for metallographic<br />

examination in accordance with ASTM E-92, at locations indicated in figure 6.2.6.2 (b) of this<br />

specification. Indentation in the Heat Affected Zone (HAZ) shall start as close to the fusion line as<br />

possible. The resulting Vickers hardness value at any point shall not exceed 248 HV10. Modalities<br />

of retest shall be in accordance with para 9.12.2 of API Spec. 5L.<br />

Reverse Bend Test (For EW Pipes only)<br />

Reverse bend test shall be executed with the same number of tests and retests<br />

specified for flattening tests in para 9.3.2 of API Spec. 5L. Ring Specimen of width 100mm to<br />

115mm shall be taken from the pipe and tested in accordance with the procedure given below<br />

and Fig 6.2.7 of this specification.<br />

Selection of Mandrel<br />

The reverse bend test shall be carried out with a mandrel, whose radius (R), or width (A) shall<br />

be calculated for any combination of diameter, wall thickness and grade with the following<br />

formula.<br />

1.4 ( D – t ) t<br />

A = 2R = ------------------------ - t<br />

e ( D - 2t ) - 1.4t<br />

Where<br />

D - Specified Outside diameter of pipe, mm<br />

t - Specified Wall thickness of pipe, mm<br />

1.4 - Peaking factor<br />

e - Strain<br />

Minimum values of `e' shall be as follows :<br />

Grades of Steel Min `e' value<br />

Gr.B : 0.1425<br />

X-42 : 0.1375<br />

X-46 : 0.1325<br />

X-52 : 0.1250<br />

X-60 : 0.1125<br />

<strong>GAIL</strong> (INDIA) LIMITED CARBON STEEL LINE PIPES <strong>GAIL</strong>-TS-LINEPIPE-CS<br />

Page 8 of 37