Volume-II - GAIL

Volume-II - GAIL

Volume-II - GAIL

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

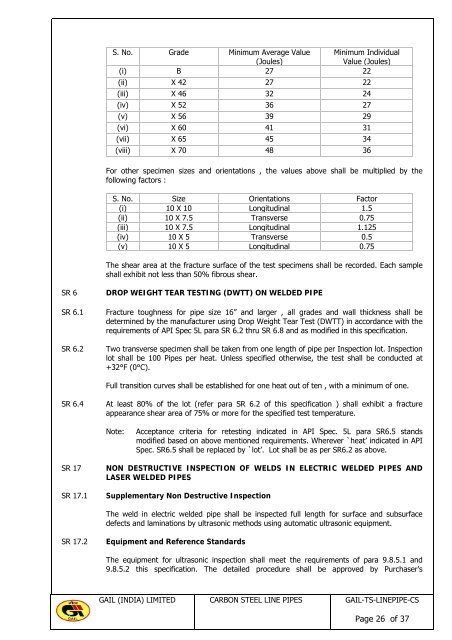

S. No. Grade Minimum Average Value Minimum Individual<br />

(Joules)<br />

Value (Joules)<br />

(i) B 27 22<br />

(ii) X 42 27 22<br />

(iii) X 46 32 24<br />

(iv) X 52 36 27<br />

(v) X 56 39 29<br />

(vi) X 60 41 31<br />

(vii) X 65 45 34<br />

(viii) X 70 48 36<br />

For other specimen sizes and orientations , the values above shall be multiplied by the<br />

following factors :<br />

S. No. Size Orientations Factor<br />

(i) 10 X 10 Longitudinal 1.5<br />

(ii) 10 X 7.5 Transverse 0.75<br />

(iii) 10 X 7.5 Longitudinal 1.125<br />

(iv) 10 X 5 Transverse 0.5<br />

(v) 10 X 5 Longitudinal 0.75<br />

The shear area at the fracture surface of the test specimens shall be recorded. Each sample<br />

shall exhibit not less than 50% fibrous shear.<br />

SR 6 DROP WEIGHT TEAR TESTING (DWTT) ON WELDED PIPE<br />

SR 6.1 Fracture toughness for pipe size 16” and larger , all grades and wall thickness shall be<br />

determined by the manufacturer using Drop Weight Tear Test (DWTT) in accordance with the<br />

requirements of API Spec 5L para SR 6.2 thru SR 6.8 and as modified in this specification.<br />

SR 6.2 Two transverse specimen shall be taken from one length of pipe per Inspection lot. Inspection<br />

lot shall be 100 Pipes per heat. Unless specified otherwise, the test shall be conducted at<br />

+32°F (0°C).<br />

Full transition curves shall be established for one heat out of ten , with a minimum of one.<br />

SR 6.4 At least 80% of the lot (refer para SR 6.2 of this specification ) shall exhibit a fracture<br />

appearance shear area of 75% or more for the specified test temperature.<br />

Note: Acceptance criteria for retesting indicated in API Spec. 5L para SR6.5 stands<br />

modified based on above mentioned requirements. Wherever `heat’ indicated in API<br />

Spec. SR6.5 shall be replaced by `lot’. Lot shall be as per SR6.2 as above.<br />

SR 17 NON DESTRUCTIVE INSPECTION OF WELDS IN ELECTRIC WELDED PIPES AND<br />

LASER WELDED PIPES<br />

SR 17.1 Supplementary Non Destructive Inspection<br />

The weld in electric welded pipe shall be inspected full length for surface and subsurface<br />

defects and laminations by ultrasonic methods using automatic ultrasonic equipment.<br />

SR 17.2 Equipment and Reference Standards<br />

The equipment for ultrasonic inspection shall meet the requirements of para 9.8.5.1 and<br />

9.8.5.2 this specification. The detailed procedure shall be approved by Purchaser's<br />

<strong>GAIL</strong> (INDIA) LIMITED CARBON STEEL LINE PIPES <strong>GAIL</strong>-TS-LINEPIPE-CS<br />

Page 26 of 37