the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP PROJECT QIJARTERX,Y PRQCRESS REPORT<br />

mixture intimately mixed. The capsule<br />

is <strong>the</strong>n tilted so that <strong>the</strong> ball closes<br />

<strong>the</strong> lower valve and isolates <strong>the</strong> upper<br />

part of <strong>the</strong> salt phase, which is <strong>the</strong>n<br />

solidified 2nd analyzed for its<br />

potassium content. The data obtained<br />

are summarized in Table 10.4.<br />

PRODUCTION AND PURIFICATION OF<br />

FLUORIDE MIXTURES<br />

F. F. Blankenship G. J. Nessle<br />

Materials Chemistry Division<br />

IJse of <strong>the</strong> hydrogenation-hydro-<br />

fluorination process previously<br />

described for fuel-sample preparation<br />

has been continued on laboratory and<br />

pilot scales for production of standard<br />

materials for corrosion testing,<br />

physical property evaluat,ion, and<br />

1 arge -component t es t ing .<br />

Construction of <strong>the</strong> production<br />

equipment to furnish 3000 lb of NaZrFS<br />

for <strong>the</strong> ARE is in an advanced stage.<br />

Raw materials are being accumulated at<br />

a satisfactory rate.<br />

A modification of <strong>the</strong> purification<br />

treatment has been adopted for micro-<br />

scale processing of samples containing<br />

enriched uranium for radiation-damage<br />

testing.<br />

Aslight modification of <strong>the</strong> standard<br />

procedure has been used successfully<br />

to purify mixtures containing 50<br />

mole % NaF, 25 mole % ZrF4, and 25<br />

mole % UF,.<br />

Preparation of NaZrF5 by direct<br />

hydrofluorination of ZrO, in <strong>the</strong><br />

presence of NaF has been moderately<br />

successful in simple equipnien t. Fur<strong>the</strong>r<br />

study of this process is planned.<br />

-<br />

122<br />

Labor at0 ry - Sc a1 e Foe 1 P reparation<br />

(13. E. Thoma, C. M. Blood, F. P. Boody,<br />

Materials Chemistry Division) . Fourteen<br />

batches of purified molten fluoride<br />

compositions, both coolant and fuel,<br />

have been prepared for loop tests,<br />

measurement of physical properties,<br />

and corrosion testing. These were<br />

treated in essentially <strong>the</strong> same manner<br />

as previously reported.(")<br />

To explore <strong>the</strong> unlikely possibility<br />

that hydrogen reduces UF, or ZrF,,<br />

two of <strong>the</strong> fuel batches were given an<br />

additional hydrogenation for 1 hr<br />

following <strong>the</strong> regular procedure. No<br />

evidence of reduced phases in <strong>the</strong><br />

products from <strong>the</strong>se runs was shown by<br />

examination with <strong>the</strong> petrographic<br />

microscope. However <strong>the</strong>re is evidence<br />

that <strong>the</strong> material so prepared was<br />

slightly less corrosive in small-scale<br />

tests than was <strong>the</strong> standard fuel. No<br />

explanation for this effect has been<br />

suggested; however, fur<strong>the</strong>r study of<br />

this behavior is planned.<br />

Modifications of techniques of<br />

assembling and disassembling apparatus<br />

have resulted in less frequent failure<br />

than was experienced at <strong>the</strong> beginning<br />

of <strong>the</strong> hydrofluorination program.<br />

Corrosion of <strong>the</strong> reactors has not yet<br />

been a problem when <strong>the</strong> standard<br />

treatment is applied to relatively<br />

pure fluoride mixtures.<br />

Pilot-Scale Fuel Purification<br />

(G. J. Nessle, J. E. Eorgan, Materials<br />

Chemistry Division). Two apparatus<br />

capable of producing up to 3 kg of<br />

('"C. M. Blood, F. P. Boody, A. J. Weinberger,<br />

and G. J. Nessle, ANP Quar. Prog. Rep. June 10.<br />

1952, ORNL-1294, p. 97.<br />

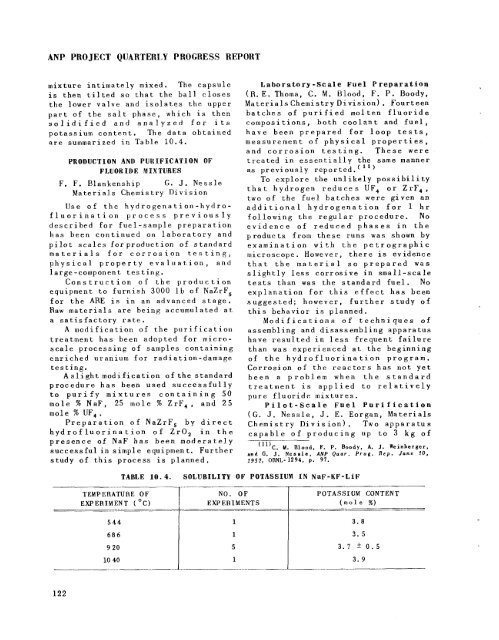

TABLE 10.4. SOLUBILITY OF POTASSIUM IN NaF-KF-LiF<br />

........ ._._____-<br />

_.<br />

TEMPERATURE OF NO. OF<br />

POTASSIUM CONTENT<br />

EXPERIMENT (OC) E XP En I ME NT S<br />

(mol@ %)<br />

..... ....... .... .... ......<br />

544<br />

68 6<br />

9 20<br />

10 40<br />

....... 1<br />

I L<br />

.... ......... ._-I.<br />

3.8<br />

3. 5<br />

3.7 * 0.5<br />

3.9

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)