the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ANP PRQ JECT QUARTERLY PROGRESS RQEO<br />

times when high urani urn conc en tra tioris<br />

are used.<br />

A test was run in <strong>the</strong> tilting<br />

furnace under standard conditions of<br />

time and temperature with NaF-ZrF4-UF,<br />

(50-46-4 mole %) that had been treated<br />

with hydrogen after purification by<br />

<strong>the</strong> norma 1 hydrogena tion-hydro fluor i -<br />

nation method. Type 316 stainless<br />

steel showed somewhat less attack when<br />

subjected to <strong>the</strong> hydrogen-treated<br />

material than when exposed to material<br />

prepared in <strong>the</strong> standard fashion. The<br />

Inconel tubes were found to be lightly<br />

attacked (0.5- to 1-mil penetration)<br />

when in contact with <strong>the</strong> hydrofluorin-<br />

ated material, but <strong>the</strong>y evidenced no<br />

atthck when exposed to <strong>the</strong> hydrogen-<br />

treated material. These preliminary<br />

tests indicate that a final hydrogen<br />

treatment of <strong>the</strong> fuel would be bene-<br />

ficial. Additional tests are scheduled.<br />

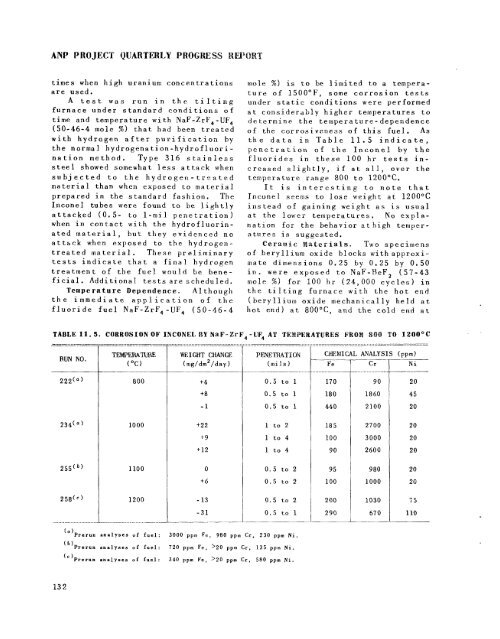

Temperature Dependence. Although<br />

<strong>the</strong> immediate application of <strong>the</strong><br />

fluoride fuel NaF-ZrF4 -UF, (50-46-4<br />

mole %) is to be limited t.0 a tempera-<br />

ture of 1500"FJ some corrosion tests<br />

under static conditions were performed<br />

at considerdbly higher temperatures to<br />

determine <strong>the</strong> temperature-dependence<br />

of <strong>the</strong> corrosiveness of this fuel. As<br />

<strong>the</strong> data in Table 11.5 indicate,<br />

penetration of <strong>the</strong> Inconel by <strong>the</strong><br />

fluorides in <strong>the</strong>se 100 hr tests in-<br />

creased slightly, if at all, over <strong>the</strong><br />

ternperaturc range 800 to 1200°C.<br />

It is interesting to note that<br />

Inconel seems to lose weight at 1200°C<br />

instead of gaining weight as is usual<br />

at <strong>the</strong> lower temperatures. No expla-<br />

nation for <strong>the</strong> behavior at high temper-<br />

atures is suggested.<br />

Ceramic Materials. Two specimens<br />

of beryllium oxide blocks with approxi-<br />

mate dimensions 0.25 by 0.25 by 0.50<br />

in. were exposed t,o NaF-BeF2 (57-43<br />

mole %) for 100 hr (24,000 cycles) in<br />

<strong>the</strong> tilting furnace with <strong>the</strong> hot end<br />

(beryllium oxide mechanically held at<br />

hot end) at 800"CJ and <strong>the</strong> cold erld at<br />

TABLE 11.5. CORROSION OF INIONEL BY NaF-ZrF4-UF4 AT TEMPERATURES PROI $B<br />

- .I_<br />

~. .<br />

RUN NO.<br />

13 2<br />

800<br />

1000<br />

1100<br />

1200<br />

'a)Prerun analyses of fuel:<br />

("Prerun analyses of fuel:<br />

("Prerun analyses of fuel:<br />

__ .......<br />

...............<br />

WEIGHT CHANCE<br />

( mg/dm2/day 1<br />

+4<br />

+8<br />

-1<br />

+22<br />

4-9<br />

+12<br />

0<br />

+6<br />

- 13<br />

-31<br />

._ .____<br />

....<br />

...<br />

0.5 to 1<br />

0.5 to 1<br />

0.5 to 1<br />

1 to 2<br />

1 to 4<br />

1 to 4<br />

0.5 to 2<br />

0.5 to 2<br />

0.5 to 2<br />

0.5 to 1<br />

3000 ppm Fe, 980 ppm Cr, 230 ppm Ni.<br />

720 ppm Fe, >20 ppm Cr, 135 ppm Ni.<br />

340 ppm Fe, >20 ppm Cr, 580 ppm Ni.<br />

....... ~<br />

........<br />

CHEMICAL ANALYSIS (ppm) .~<br />

Fe<br />

Cr<br />

Ni<br />

170<br />

180<br />

440<br />

18 5<br />

100<br />

90<br />

95<br />

100<br />

2 00<br />

290<br />

90<br />

1860<br />

2100<br />

2700<br />

3000<br />

2600<br />

980<br />

1000<br />

1030<br />

61 0<br />

20<br />

45<br />

20<br />

20<br />

20<br />

20<br />

20<br />

20<br />

75<br />

110

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)