the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP PROJECT QUARTERLY PROGRESS REPORT<br />

MATERIAL<br />

4<br />

a<br />

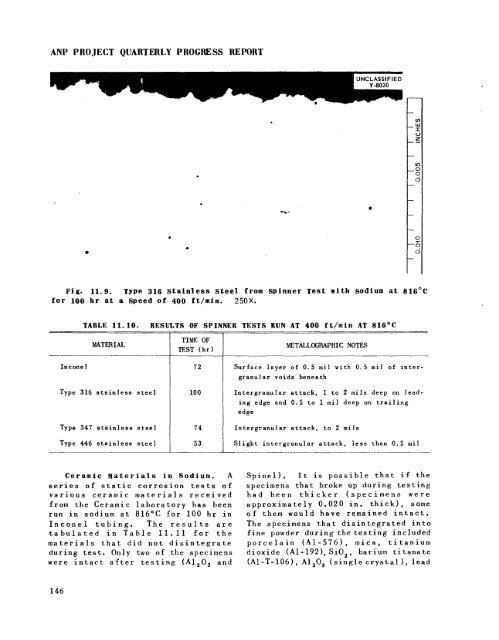

Fig. 11.9. Type 316 stainless steel from Spinner Test with sodium at 816OC<br />

for 100 hr at a Speed of 400 ft/min. 250X.<br />

Inconel<br />

Type 316 stainless steel<br />

Type 347 stainless steel<br />

Type 446 stainless steel<br />

TIME OF<br />

TEST (hr)<br />

72<br />

100<br />

Ceramic Materials in Sodium. A<br />

series of static corrosion tests of<br />

various ceramic materials received<br />

from <strong>the</strong> Ceramic laboratory has been<br />

run in sodium at 816°C for 100 hr in<br />

Inconel tubing. The results are<br />

tabulated in Table 11.11 for <strong>the</strong><br />

materials that did not disintegrate<br />

during test. Only two of <strong>the</strong> specimens<br />

were intact after testing (A1,0, and<br />

146<br />

74<br />

53<br />

METALLOGRAPHIC NOTFS<br />

Surface layer of 0.5 mil with 0.5 mil of inter-<br />

granular voids beneath<br />

Intergranular attack, 1 to 2 mils deep on lead-<br />

ing edge and 0.5 to 1 mil deep on trailing<br />

edge<br />

Intergranular attack, to 2 mils<br />

Slight intergranular attack, less than 0.5 mil<br />

Spinel). It is possible that if <strong>the</strong><br />

specimens that broke up during testing<br />

had been thicker (specimens were<br />

approximately 0,020 in, thick), some<br />

of <strong>the</strong>m would have remained intact.<br />

The specimens that disintegrated into<br />

fine powder during <strong>the</strong> testing included<br />

porcelain (A1-576), mica, titanium<br />

dioxide (A1-192), SiO,, barium titanate<br />

(Al-T-106), A1,0, (single crystal ), lead<br />

8

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)