the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

corrodant under iso<strong>the</strong>rmal conditions.<br />

Inconel and types 316, 347, and 446<br />

stainless steels have been tested in<br />

this apparatus. Greater attack than<br />

that obtained in ordinary static cor-<br />

rosion tests was noted onall materials<br />

tested. It should be emphasized that,<br />

except in <strong>the</strong> test of <strong>the</strong> type 347<br />

stainless steel specimens, <strong>the</strong>se were<br />

actually three-component tests because<br />

<strong>the</strong> spinner pot was fabricated of type<br />

347 stainless steel.<br />

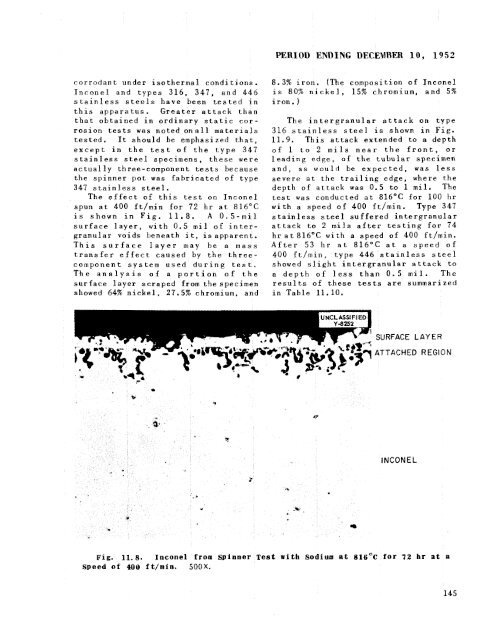

The effect of this test on Inconel<br />

spun at 400 ft/min for 72 hr at 816°C<br />

is shown in Fig. 11.8. A 0.5-mil<br />

surface layer, with 0.5 m i l of inter-<br />

granular voids beneath it, is apparent.<br />

This surface layer may be a mass<br />

transfer effect caused by t,he three-<br />

component system used during test.<br />

The analysis of a portion of <strong>the</strong><br />

surface layer scraped from <strong>the</strong> specimen<br />

showed 64% nickel, 27.5% chromium. and<br />

PERIOD ENDING DECEUBER 10, 1952<br />

8.3% iron. (The composition of Inconel<br />

is 80% nickel, 15% chromium, and 5%<br />

iron. 1<br />

The intergranular attack on type<br />

316 stainless steel is shown in Fig.<br />

11.9. This attack extended to a depth<br />

of 1 to 2 m i l s near <strong>the</strong> front, or<br />

leading edge, of <strong>the</strong> tubular specimen<br />

and, as would he expected, was less<br />

severe at <strong>the</strong> trailing edge, where <strong>the</strong><br />

depth of attack was 0.5 to 1 m il. The<br />

test was conducted at 816°C for 100 hr<br />

with a speed of 400 ft/min. Type 347<br />

stain 1 ess s tee 1 suffered intergranular<br />

attack to 2 m i l s after testing for 74<br />

hr at 816°C with a speed of 400 ft/min.<br />

After 53 hr at 816°C at a speed of<br />

400 ft/rnin, type 446 stainless steel<br />

showed slight intergranular attack to<br />

a depth of less than 0.5 m i l . The<br />

results of <strong>the</strong>se tests are summarized<br />

in Table 11.10.<br />

SURFACE LAYER<br />

ATTACHED REGION<br />

INCONEL<br />

Fig. 11.8. Inconel from Spinner Test with Sodium at 816OC for 72 hr at a<br />

Speed of 400 ft/ein. 500X.<br />

145

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)