the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

filling, fluoride leakage occurred at<br />

only 1-psi pressure. The leakage soon<br />

stopped, and <strong>the</strong> gas flow was somewhat<br />

retarded. When <strong>the</strong> pressure was<br />

increased to3 psi, most of <strong>the</strong> fluoride<br />

was forced from <strong>the</strong> container. Exami-<br />

nation showed that only a small amount<br />

of fluoride had adhered to <strong>the</strong> braid.<br />

Attempts were made to run tests of<br />

molybdenum disulfide and nickelic<br />

oxide, but <strong>the</strong>se materials were so<br />

“fluid” that <strong>the</strong> container would not<br />

hold <strong>the</strong>m. Parts with smaller clear-<br />

ances are being fabricated.<br />

Face Seal Tests. Face seals are<br />

being considered for high- temperature<br />

use with both gases and liquids. All<br />

tests have been run in air at room<br />

temperature with speeds of about,<br />

1600 rpm and pressures of up to 14 psi.<br />

The following combinations of materials<br />

were tested in air, without added<br />

1 u b r i cat i on :<br />

Carboloy (grade 779) vs. Carboloy (grade 779)<br />

Carboloy (grade 779) VS. graphite (grade C-18)<br />

Graphite (grade C-18) VS. graphite (grade C-18)<br />

In <strong>the</strong> t.est of Carboloyvs. Carboloy,<br />

a loud, grinding noise developed<br />

within 5 min, and inspection showed<br />

that annular grooves had been worn<br />

into each surface. Operation with <strong>the</strong><br />

o<strong>the</strong>r two combinations of materials<br />

was satisfactory until chattering<br />

developed when a temperature of about<br />

550’F was reached at <strong>the</strong> seal because<br />

of <strong>the</strong> heat of friction. If graphite<br />

depends upon a layer of tightly held<br />

moisture for some of its lubrication<br />

I -<br />

I_._I.-. -<br />

1150<br />

30 1200<br />

37 1200<br />

- __<br />

._ __I I__ -<br />

PERIOD ENDING DECEMBER 10, 1952<br />

qualities,(3 8‘) <strong>the</strong>n this chattering<br />

may be due to <strong>the</strong> driving-off of<br />

surface-held moisture at a more rapid<br />

rate than it can be supplied by<br />

diffusion from <strong>the</strong> interior of <strong>the</strong><br />

graphite. The time required for <strong>the</strong><br />

test seals to reach <strong>the</strong> chattering<br />

stage was usually between 1/2 and<br />

4 hr; however, in one test <strong>the</strong> Carboloy<br />

vs. graphite seal operated satis-<br />

factorily for 42 hours. The area of<br />

seal contact was 1 1/2 in.‘ in each<br />

test, and <strong>the</strong> seal contact force was<br />

varied from 5 to 20 pounds. Similar<br />

results were obtained when Carboloy<br />

VS. graphite seals were tested with<br />

MoSz and RbOH used as lubricants.<br />

A1 though some seals showed relatively<br />

little chattering, <strong>the</strong>rewas, generally,<br />

a marked increase in <strong>the</strong> torque<br />

required to overcome <strong>the</strong> seal friction<br />

as <strong>the</strong> seals heated up.<br />

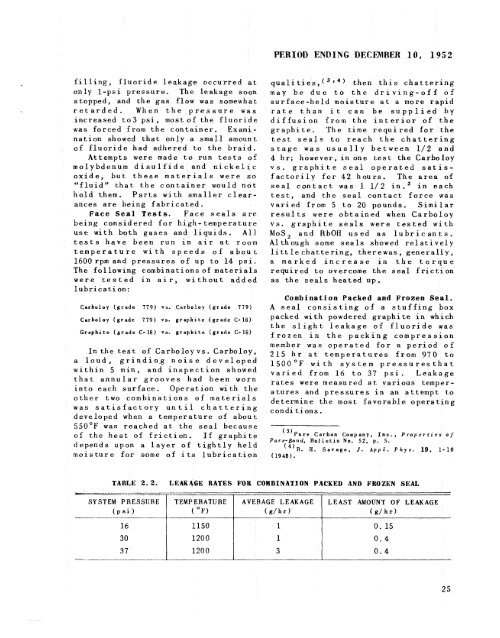

Combination Packed and Frozen Seal.<br />

A seal consisting of a stuffing box<br />

packed with powdered graphite in which<br />

<strong>the</strong> slight leakage of fluoride was<br />

frozen in <strong>the</strong> packing compression<br />

member was operated for a period of<br />

215 hr at temperatures from 970 t o<br />

1500’F with system pressuresthat<br />

varied from 16 to 37 psi. Leakage<br />

rates were measured at various temper-<br />

atures and pressures in an attempt to<br />

determine <strong>the</strong> most favorable operating<br />

conditions.<br />

(3)P~re Carbon Company, Inc., Properties of<br />

Pure-Bond, Bulletin No. 52. p. 5.<br />

t4)R.<br />

(1948).<br />

H. Savage, J. Appl. Phys. 19. 1-10<br />

AVERAGE LEAKAGE LEAST AMOUNT OF LEAKAGE<br />

(g/hr) (g/hr)<br />

1 0. 15<br />

1 0.4<br />

3 0.4<br />

_I<br />

25

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)