the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP PROJECT QUARTERLY PROGRESS REPORT<br />

to be used in <strong>the</strong> ARE was made to aid<br />

in <strong>the</strong> interpretation of BeO-NaK<br />

compatibility test data. These blocks,<br />

fabricated by <strong>the</strong> Norton Go., were<br />

made by hot-pressing Be0 powder. They<br />

are hexagonal blocks 2 1/8 in. on a<br />

side, 3 11/16 in. in diameter across<br />

center of faces, and 6 in. long. They<br />

are fabricated with a center hole<br />

running axially through <strong>the</strong> block;<br />

<strong>the</strong> diameter of <strong>the</strong> hole (depending on<br />

<strong>the</strong> position of <strong>the</strong> block in <strong>the</strong><br />

reactor core) is 1/2, 1 i/8, or 1 3/4<br />

inches. A visual examination was<br />

made of about 30 blocks of <strong>the</strong> type<br />

having a 1/2-in.-dia hole. These<br />

blocks had been sawed in two on a<br />

plane perpendicular to <strong>the</strong> long axis.<br />

It was observed that in all cases <strong>the</strong><br />

core of <strong>the</strong> blocks had a different<br />

physical structure than did <strong>the</strong> outer<br />

portion of <strong>the</strong> same blocks. In order<br />

to study this core structure, s i x<br />

blocks that had not been sawed were<br />

soaked in fuchsin dye for 12 hours.<br />

The dye is mosc absorbed in <strong>the</strong> more<br />

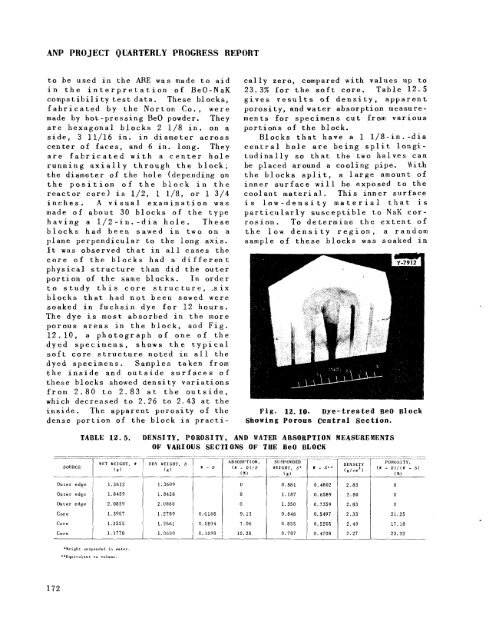

porous areas in <strong>the</strong> block, and Fig.<br />

12.10, a photograph of one of <strong>the</strong><br />

dyed specimens, shows <strong>the</strong> typical<br />

soft core structure noted in all <strong>the</strong><br />

dyed specimens. Samples taken from<br />

<strong>the</strong> inside and outside surfaces of<br />

<strong>the</strong>se blocks showed dens1 ty variations<br />

from 2.80 to 2.83 at <strong>the</strong> outside,<br />

which decreased to 2.26 to 2.43 at <strong>the</strong><br />

inside. The apparent porosity of <strong>the</strong><br />

dense portion of <strong>the</strong> block is practi-<br />

Core<br />

Core<br />

Core<br />

cally zero, compared with values up to<br />

23.3% for <strong>the</strong> soft core. Table 12.5<br />

gives results of density, apparent<br />

porosity, and water absorption measure-<br />

ments for specimens cut from various<br />

portions of <strong>the</strong> block.<br />

Blocks that have a 1 1/8-in.-dia<br />

central hole are being split longi-<br />

tudinally so that <strong>the</strong> two halves can<br />

be placed around a cooling pipe. With<br />

<strong>the</strong> blocks split, a large amount of<br />

inner surface w i l l he exposed to <strong>the</strong><br />

coolant material. This inner surface<br />

is low-density material that is<br />

particularly susceptible to NaK cor-<br />

rosion. To determine <strong>the</strong> extent of<br />

<strong>the</strong> low density region, a random<br />

sample of <strong>the</strong>se blocks was soaked in<br />

Fig. 12.10. Dye-treated BeO Block<br />

Showing Porous central Section.<br />

TABLE 12. 5. DENSITY, POROSITY, AND WATER ABSORPTION MEASUREMENTS<br />

OF VARIOUS SECTIONS OF THE Be0 BLOCK<br />

0.881 0.4802 2.83<br />

1.187 0.6589 2.80<br />

1.3957<br />

1.3555<br />

1.2789<br />

1.2661<br />

0:1168<br />

0.0894 1 9.13<br />

7.06<br />

1.350<br />

0.846<br />

0.835<br />

0.7359<br />

0.5497<br />

0.5205<br />

2.83<br />

2.33<br />

2.43<br />

0<br />

21.25<br />

17.18<br />

1.1778 1.0630 0.1098 1 10.28 0.707 0.4708 2.27<br />

23.32

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)