the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP PROJECT QUARTERLY PROGRESS REPORT<br />

more severely than those exposed to<br />

<strong>the</strong> liquid phase. Inconel, type 309<br />

stainless steel, and type 316 stainless<br />

steel appeared to be attacked by <strong>the</strong><br />

vapor phase to approximately <strong>the</strong> same<br />

extent as by <strong>the</strong> liquid phase of <strong>the</strong><br />

molten fluoride salt. Figures 11.1<br />

and 11.2 compare type 304 stainless<br />

steel as exposed to <strong>the</strong> liquid phase<br />

and to <strong>the</strong> vapor phase of <strong>the</strong> fluoride.<br />

Details of <strong>the</strong>se tests are presented<br />

in Table 11.2.<br />

Crevice Corrosion. Some concern had<br />

been expressed about <strong>the</strong> possibility<br />

of crevice corrosion in materials used<br />

to contain <strong>the</strong> molten fluorides. In<br />

order to check this possibility, tests<br />

were set up with specially prepared<br />

crevices. Ordinary static corrosion<br />

tubes were employed, and <strong>the</strong> lower<br />

section of <strong>the</strong> tube above <strong>the</strong> bottom<br />

___<br />

Erratic attack, subsurface voids<br />

to 1.5 mils<br />

Er re t i c attack ~ inter gr anu 1 ar<br />

with some subsurface voids to 1 mil<br />

Subsuriace voids to 3 mils<br />

Intergranular penetration of 1 mil<br />

weld was partly crimped so that a<br />

crevice about 1 in. long and approxi-<br />

mately 1/16 in. wide was obtained.<br />

After being exposed for 100 hr at<br />

816°C to <strong>the</strong> fluoride mixture NaF-KF-<br />

LiF-UF, (10.9-43.5-44.5-1.1 mole %I,<br />

<strong>the</strong> tubes were cut longitudinally<br />

through <strong>the</strong> partly crimped section and<br />

examined for evidence of accelerated<br />

corrosion. The crimped ends of several<br />

ordinary static corrosion test tubes<br />

were also examined for accelerated<br />

corrosion. Corrosion in <strong>the</strong>se crevices<br />

appeared to be somewhat erratic, with<br />

some sections being unattacked. How-<br />

ever, even in <strong>the</strong> sections that were<br />

attacked, <strong>the</strong> depth of penetration did<br />

not exceed that normally expected for<br />

<strong>the</strong>se materials after exposure to<br />

fluorides. Details of <strong>the</strong>se tests are<br />

presented in Table 11.3.<br />

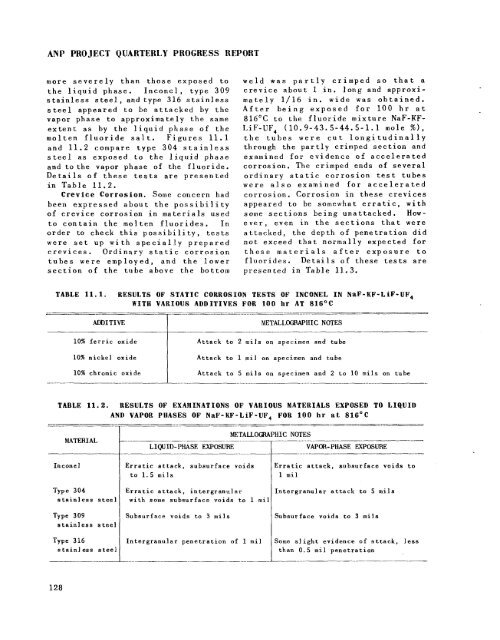

TABLE 11.1. RESULTS OF STATIC CORROSION TESTS OP INCONEL IN NaF-KF-LiF-UF,<br />

WITH VARIOUS ADDITIVES FOR 1100 hr AT 8lfiOC<br />

____ ...<br />

.ADDITIVE<br />

10% ferric oxide<br />

10% nickel oxide<br />

10% chromic oxide<br />

........ __._I__<br />

METALLOGRAPHIC NOTES<br />

-_....___ .<br />

Attack to 2 mils on specimen and tube<br />

Attack to 1 m il on specimen and tube<br />

Attack to 5 mils on specimen and 2 to 10 mils on tube<br />

TABLE 11.2. RESULTS OF EXAMINATIONS OF VARIOUS MATERIALS EXPOSED TO LIQUID<br />

AND VAPOR PHASES OF NaF-KF-LiF-UF, FOR 100 hr at 816OC<br />

hIATERIA1.<br />

In cone I<br />

Type 304<br />

stainless steel<br />

Type 309<br />

stainless steel<br />

Type 316<br />

s tainl ess s tee1<br />

..- ..<br />

.... .... ________._<br />

....._______ ...______ ..-. ..-. .<br />

METALLOGRAPHIC NOTES<br />

...______ .......<br />

LIQUID- PHASE EWOSURE 7""'vaPm- PHASE EXPOSURE<br />

Erratic attack, subsurface voids to<br />

1 mil<br />

Intergranular attack to 5 mils<br />

Subsurface voids to 3 mils<br />

_.I-<br />

Some slight evidence of attack, Jess<br />

than 0.5 mil penetration

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)