the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ANP PROJECT QUARTERLY PROGRESS REPORT<br />

-<br />

0- 4<br />

B- 5<br />

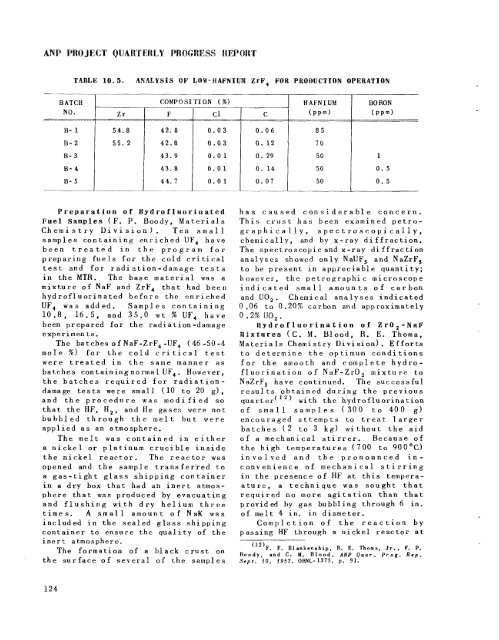

TABLE 10.5. ANALYSIS OF LOW- APNIUM ZrF, FOR PRODUCTION OPERATION<br />

RATCH<br />

~. COMPO SI TI ON ( %)<br />

.. .. . .<br />

HAFNIUM<br />

NO. Zr F Cl C<br />

43. a 0.01<br />

44. I 0.01<br />

P rep ar at i o n o f My d 1-0 f 1 u o r i PI a& e d<br />

Fuel samples (F. P. Boody, Materials<br />

Chemistry Division). Ten small<br />

samples containing enriched UF, have<br />

been treated in <strong>the</strong> program for<br />

preparing fuels for <strong>the</strong> cold critical<br />

test and for radiation-damage tests<br />

in <strong>the</strong> MTR. The base material was a<br />

mixture of NaF and ZrF, that had been<br />

hydrofluorinated before <strong>the</strong> cnriched<br />

UF, was added. Samples containing<br />

10.8, 16.5, and 35.0 w t % UF, have<br />

been prepared for <strong>the</strong> radiation-damage<br />

experiments.<br />

The batches of NaF-ZrF, -IJF, (45 -50 -4<br />

mole %) for <strong>the</strong> cold critical test<br />

were treated in <strong>the</strong> same manner as<br />

bat,ches containingnormal UF,. However,<br />

<strong>the</strong> batches required for radiationdamage<br />

tests were small (10 to 20 g),<br />

and <strong>the</strong> procedure was modified so<br />

that <strong>the</strong> HF, H,, and He gases were not<br />

bubbled through <strong>the</strong> melt but were<br />

applied as an atmosphere.<br />

The melt was contained in ei<strong>the</strong>r<br />

a nickel or platinum crucible inside<br />

<strong>the</strong> nickel reactor. The reactor wzs<br />

opened and <strong>the</strong> sample transfer'red to<br />

a gas-tight glass shipping cont,ainer<br />

in a dry box that had an inert atmoswhere<br />

that wits produced by evacuating<br />

and flushirig with dry helium three<br />

times. A small amount of NaK was<br />

included in <strong>the</strong> sealed glass shipping<br />

container to ensure <strong>the</strong> quality of <strong>the</strong><br />

inert atmosphere.<br />

The formation of a black crust on<br />

<strong>the</strong> surface of several of <strong>the</strong> samples<br />

124<br />

1 0.07<br />

...~ .... I ...... ~<br />

BO RON<br />

1 1 0. 14 50 0.5<br />

0.5<br />

50<br />

I<br />

I<br />

has caused considerable concern.<br />

This crust has been examined petrogr<br />

a p hi c a l l y , s p e c t r o s c o p i c a l l y ,<br />

chemically, and by x-ray diffraction.<br />

The spectroscopic and x-ray diffraction<br />

analyses showed only NaUF5 and NaZrFs<br />

to be present in appreciable quantity;<br />

however, <strong>the</strong> petrographic microscope<br />

indicat,ed s m a l l amounts of carbon<br />

and UO,. Chemical analyses indicated<br />

0.06 to 0.20% carbon and approximately<br />

0 .2% [JQ,.<br />

Hydroflusrination of ZrO,-N*aF<br />

k!lxtvres (C. M. Blood, R. E. Thoma,<br />

Materials Chemistry Division). Efforts<br />

to determine <strong>the</strong> optimum conditions<br />

for <strong>the</strong> smooth and complete hydrofluorination<br />

of NaF-ZrQ, mixtur~ to<br />

NaZrF5 have continued. The successful<br />

results obtained during <strong>the</strong> previous<br />

quarter' 2, with <strong>the</strong> hydrofluorination<br />

of small samples (300 to 400 g)<br />

encouraged attempts to treat 1 arger<br />

batches (2 to 3 kg) without <strong>the</strong> aid<br />

of a mechanical stirrer. Because of<br />

<strong>the</strong> high temperatures (700 to 900°C)<br />

involved and <strong>the</strong> pronounced inconvenience<br />

of mechanical stirring<br />

in <strong>the</strong> presence of HF at this temperaature,<br />

a technique was sought that<br />

required no more agitation than that<br />

provided by gas bubbling through 6 in.<br />

of melt 4 in. in diameter.<br />

Completion of <strong>the</strong> reaction by<br />

passing HF through a nickel reactor at<br />

(12)F. F. Blankenship, R. E. Thomn, Jr., F. P.<br />

Boody, and C. M. Blood, ANP Quar. Prog. Rep.<br />

Sept. 10, 1952. OWL-1375, p. 91.

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)