the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP PRQJECT QUARTERLY PROGRESS REPORT<br />

Pd-3% Mn alloy. As a result of this<br />

investigation, it was found that a<br />

brazing alloy in contact with one base<br />

metal may be severelyoxidized, whereas<br />

it may be relatively unattacked when<br />

in contact with ano<strong>the</strong>r base metal.<br />

This might be explained by <strong>the</strong> fact<br />

that <strong>the</strong> least oxidation -resistant<br />

constituents of <strong>the</strong> brazing alloy may<br />

diffuse more readily into certain base<br />

metals than into o<strong>the</strong>rs.<br />

Corrosion af Braz%ng Alloys by<br />

Sodium Hydroxide. Since A nickel is<br />

relatively unattacked by molten sodium<br />

hydroxide at 15Q0°F, it serves as a<br />

suitable base metal for testing <strong>the</strong><br />

corrosion resistance of brazing alloys<br />

in this medium. Examination of a<br />

joint brazed with 60% Pd-40% Ni alloy<br />

and tested in NaOH for 100 hr showed<br />

168<br />

that no attack is present. Several<br />

o<strong>the</strong>r alloys were attacked, and <strong>the</strong><br />

joints brazed with <strong>the</strong> Cr-Ni-Si-Mn and<br />

<strong>the</strong> Cr-Ni-Si alloys fractured during<br />

removal from <strong>the</strong> test capsule.<br />

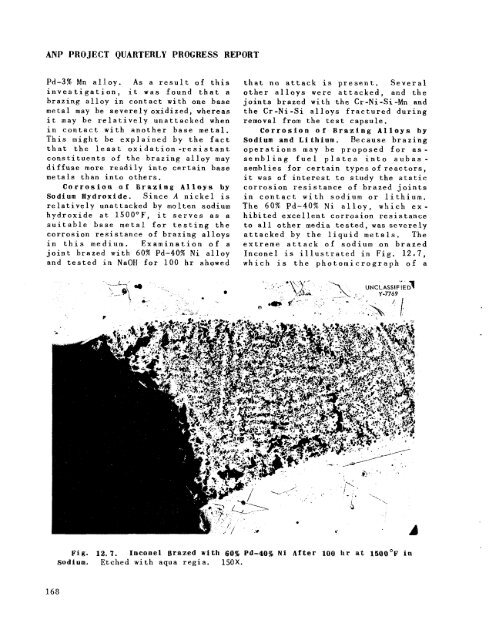

Corrosion of Brazing Alloys by<br />

Sodium and Li thiom. Because brazing<br />

operations may be proposed for as-<br />

sembling fuel plates into subas-<br />

semblies for certain types of reactors,<br />

it was of interest to study <strong>the</strong> static<br />

corrosion resistance of brazed joints<br />

in contact with sodium or lithium.<br />

The 60% Pd-4QX N i alloy, which ex-<br />

hibited excellent corrosion resistance<br />

to all o<strong>the</strong>r media tested, was severely<br />

attacked by <strong>the</strong> liquid metals. The<br />

extreme attack of sodium on brazed<br />

Inconel is illustrated in Fig. 12,7,<br />

which is <strong>the</strong> photomicrograph of a<br />

Fig. 12.7. Inconel Brazed with 60$ Pd-4Q% N i After 100 hr at 15QO0F in<br />

Sodium, Etched with aqua regia. 15QX.

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)