the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

sample tested for 100 hr at 1500°F.<br />

As a check on <strong>the</strong>se results, small<br />

specimens of <strong>the</strong> pure braze metal<br />

were immersed in <strong>the</strong> metal baths.<br />

The sample tested in sodium had a<br />

weight loss of over SOX, and <strong>the</strong><br />

sample tested in lithium completely<br />

dissolved.<br />

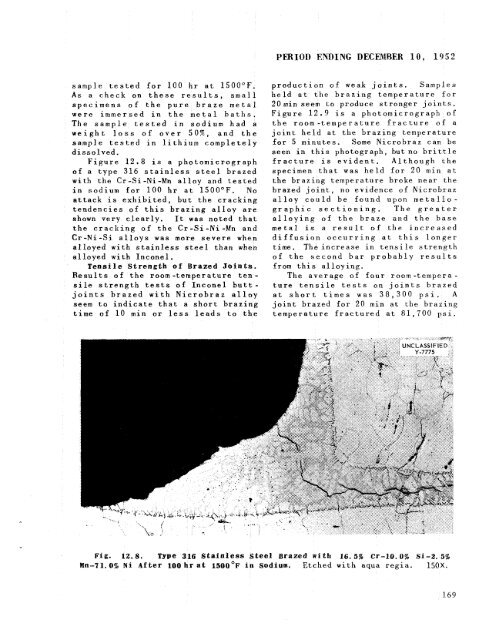

Figure 12.8 is a photomicrograph<br />

of a type 316 stainless steel brazed<br />

with <strong>the</strong> Cr-Si-Ni-Mn alloy and tested<br />

in sodium for 100 hr at 1500°F. No<br />

attack is exhibited, but <strong>the</strong> cracking<br />

tendencies of this brazing alloy are<br />

shown very clearly. It was noted that<br />

<strong>the</strong> cracking of <strong>the</strong> Cr-Si-Ni-Mn and<br />

Cr-Ni-Si alloys was more severe when<br />

alloyed with stainless steel than when<br />

a1 loyed with Inconel.<br />

Tensile Strength of Brazed Joints.<br />

Results of <strong>the</strong> room -temperature ten -<br />

sile strength tests of Inconel butt-<br />

joints brazed with Nicrobraz alloy<br />

seem to indicate that a short brazing<br />

time of 10 min or less leads to <strong>the</strong><br />

PERIOD ENDING DECEMBER 310, 1952<br />

production of weak joints. Samples<br />

held at <strong>the</strong> brazing temperature for<br />

20 min seem LO produce stronger joints.<br />

Figure 12.9 i s a photomicrograph of<br />

<strong>the</strong> room -temperature fracture of a<br />

joint held at <strong>the</strong> brazing t,emperature<br />

for 5 minutes. Some Nicrobraz can be<br />

seen in this photograph, but no brittle<br />

fracture is evident. Although <strong>the</strong><br />

specimen that was held for 20 min at<br />

<strong>the</strong> brazing temperature broke near <strong>the</strong><br />

brazed joint, no evidence of Nicrobraz<br />

alloy could be found upon metallo-<br />

graphic sectioning. The greater<br />

alloying of <strong>the</strong> braze and <strong>the</strong> base<br />

metal is a result of <strong>the</strong> increased<br />

diffusion occurring at this longer<br />

time. The increase in tensile strength<br />

of <strong>the</strong> second bar probably results<br />

from t h i s a1 1 oy ing I<br />

The average of four room-temperature<br />

tensile tests on joints brazed<br />

at short times was 38,300 psi. A<br />

joint brazed for 20 min at <strong>the</strong> brazing<br />

temperature fractured at 81,100 psi.<br />

Fig. 12.8. Type 316 Stainless Steel Brazed with 16.5% Cr-la. 0% Si-2. 55%<br />

Wn-ll.O$ N i After 100 hr at lSOO°F in sodium. Etched with aqua regia. 150X.<br />

169

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)