ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

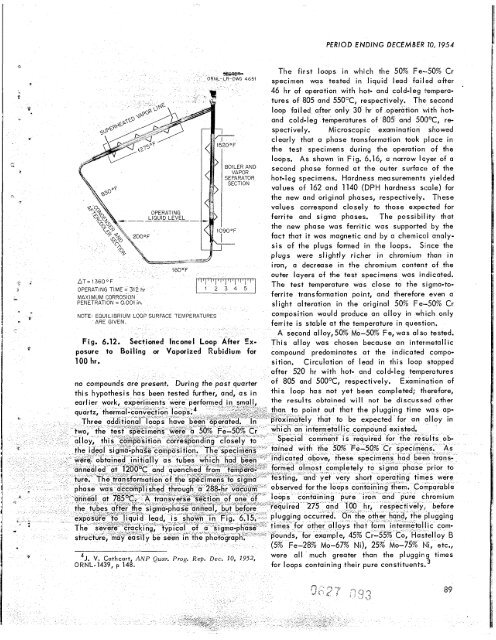

AT= 136OOF<br />

OPERATING TIME = 312 hr<br />

MAXIMUM CORROSION<br />

PENETRATION = 0 001 in.<br />

i6O0F<br />

NOTE EQUILIBRIUM LOOP SURFACE TEMPERATURES<br />

ARE GIVEN.<br />

-<br />

0°F<br />

4651<br />

BOILER AND<br />

VAPOR<br />

SEPARATOR<br />

SECTION<br />

30°F<br />

-<br />

1 1 2 3 4 5 1<br />

Fig. 6.12. Sectioned lnconel Loop After Ex-<br />

posure to Boiling or Vaporized Rubidium for<br />

100 hr.<br />

During - <strong>the</strong> past quarter<br />

this hypo<strong>the</strong>sis has been tested fur<strong>the</strong>r, and, as in<br />

,.<br />

PERlOD ENDING DECEMBER 70, 1954<br />

The first loops in which <strong>the</strong> 50% Fe--50% Cr<br />

specimen was tested in liquid lead failed after<br />

46 hr of operation with hot- and cold-leg Vempera-<br />

tures of 805 and 550°C, respectively. The second<br />

loop failed after only 30 hr of o<br />

and cold-leg temperatures of 805 and 5OO0C, re-<br />

spect ivel y. Microscopic examination showed<br />

clearly that a phase transformation took piece in<br />

<strong>the</strong> test specimens during <strong>the</strong> operation of <strong>the</strong><br />

loops. As shown in Fig, 6.16, a narrow layer of a<br />

second phase formed at <strong>the</strong> outer surface of <strong>the</strong><br />

hot-leg specimens, Hardness measurements yielded<br />

values of 162 and 1140 (DPH hardness scale) for<br />

<strong>the</strong> new and original phases, respectively. These<br />

values correspond closely to those expected for<br />

ferrite and sigma phases, The possibility that<br />

<strong>the</strong> new phase was ferritic was supported by <strong>the</strong><br />

fact that it was magnetic and by a chemicctl analy-<br />

sis of <strong>the</strong> plugs formed in <strong>the</strong> loops. Siince <strong>the</strong><br />

plugs were slightly richer in chromium than in<br />

iron, a decrease in <strong>the</strong> chromium content of <strong>the</strong><br />

outer layers of <strong>the</strong> test specimens was indicated.<br />

The test temperature was close to <strong>the</strong> sigma-fo-<br />

ferrite transformation point, and <strong>the</strong>refore even a<br />

slight alteration in <strong>the</strong> original 50% Fe--50% Cr<br />

composition would produce an alloy in which only<br />

ferrite is stable at <strong>the</strong> temperature in question.<br />

A second alloy, 50% Mo-50% Fe, was a1 so tested.<br />

This alloy was chosen because an intermetallic<br />

compound predominates at <strong>the</strong> indicated compo-<br />

sition, Circulation of lead in this loop stopped<br />

after 520 hr with hot- and cold-leg temperatures<br />

of 805 and 5OO0C, respectively. Examination of<br />

this loop has not yet been completed; <strong>the</strong>refore,<br />

<strong>the</strong> results obtained will not be discussed o<strong>the</strong>r<br />

for loops containing <strong>the</strong>ir pure constituents.<br />

'

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)