ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ANP QUARTERLY PROGRESS REPORT<br />

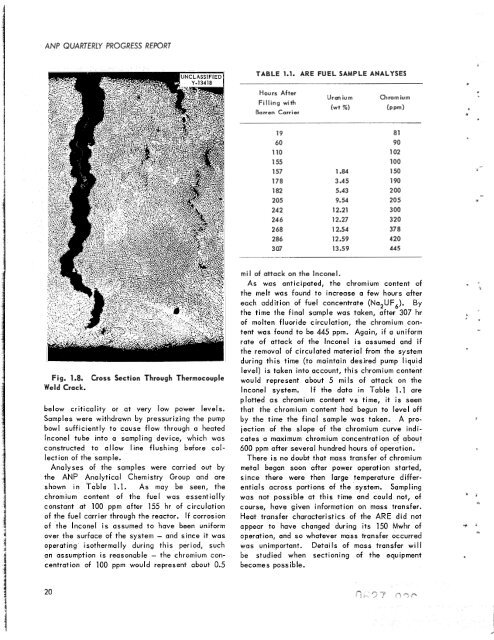

Fig. 1.8.<br />

Weld Crack.<br />

Cross Section Through Thermocouple<br />

below criticality or at very low power levels.<br />

Samples were withdrawn by pressurizing <strong>the</strong> pump<br />

bowl sufficiently to cause flow through a heated<br />

lnconel tube into a sampling device, which was<br />

constructed to allow line flushing before col-<br />

lection of <strong>the</strong> sample.<br />

Analyses of <strong>the</strong> samples were carried out by<br />

<strong>the</strong> ANP Analytical Chemistry Group and are<br />

shown in Table 1.1. As may be seen, <strong>the</strong><br />

chromium content of <strong>the</strong> fuel was essentially<br />

constant at 100 ppm after 155 hr of circulation<br />

of <strong>the</strong> fuel carrier through <strong>the</strong> reactor. If corrosion<br />

of <strong>the</strong> lnconel is assumed to have been uniform<br />

over <strong>the</strong> surface of <strong>the</strong> system - and since it was<br />

operating iso<strong>the</strong>rmally during this period, such<br />

an assumption is reasonable - <strong>the</strong> chromium con-<br />

centration of 100 ppm would represent about 0.5<br />

20<br />

TABLE 1.1. ARE FUEL SAMPLE ANALYSES<br />

Hours After<br />

Filling with<br />

Barren Carrier<br />

19<br />

60<br />

110<br />

1 55<br />

157<br />

178<br />

182<br />

205<br />

242<br />

24 6<br />

268<br />

286<br />

3 07<br />

Uranium Chromium<br />

(wt X) (PPm)<br />

1.84<br />

3.45<br />

5.43<br />

9.54<br />

12.21<br />

12.27<br />

12.54<br />

12.59<br />

13.59<br />

81<br />

90<br />

102<br />

100<br />

150<br />

190<br />

2 00<br />

205<br />

300<br />

320<br />

37 8<br />

420<br />

445<br />

mil of attack on <strong>the</strong> Inconel.<br />

As was anticipated, <strong>the</strong> chromium content of<br />

<strong>the</strong> melt was found to increase a few hours after<br />

each addition of fuel concentrate (Na,UF,). By<br />

<strong>the</strong> time <strong>the</strong> final sample was taken, after 307 hr<br />

of molten fluoride circulation, <strong>the</strong> chromium content<br />

was found to be 445 ppm. Again, if a uniform<br />

rate of attack of <strong>the</strong> lnconel is assumed and if<br />

<strong>the</strong> removal of circulated material from <strong>the</strong> system<br />

during this time (to maintain desired pump liquid<br />

level) is taken into account, this chromium content<br />

would represent about 5 mils of attack on <strong>the</strong><br />

lnconel system. If <strong>the</strong> data in Table 1.1 are<br />

plotted as chromium content vs time, it is seen<br />

that <strong>the</strong> chromium content had begun to level off<br />

by <strong>the</strong> time <strong>the</strong> final sample was taken. A projection<br />

of <strong>the</strong> slope of <strong>the</strong> chromium curve indicates<br />

a maximum chromium concentration of about<br />

600 ppm after several hundred hours of operation.<br />

There is no doubt that mass transfer of chromium<br />

metal began soon after power operation started,<br />

since <strong>the</strong>re were <strong>the</strong>n large temperature differentials<br />

across portions of <strong>the</strong> system. Sampling<br />

was not possible at this time and could not, of<br />

course, have given information on mass transfer.<br />

Heat transfer characteristics of <strong>the</strong> ARE did not<br />

appear to have changed during its 150 Mwhr of<br />

operation, and so whatever mass transfer occurred<br />

was unimportant. Details of mass transfer will<br />

be studied when sectioning of <strong>the</strong> equipment<br />

becomes possible.

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)