ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ANP QUARTERLY PROGRESS REPORT<br />

rrugated Fin Segment of a Heat<br />

d with an 82% Au-18% Ni Alloy.<br />

on <strong>the</strong> basis of short-time static tests. However,<br />

an experiment was conducted to determine <strong>the</strong><br />

influence of a high gold concentration gradient on<br />

<strong>the</strong> corrosion resistance of <strong>the</strong> internal surface<br />

of an lnconel tube when exposed to fused fluoride<br />

salt at 15OOOF.<br />

The test specimen consisted of a 1 4-in.-OD,<br />

0.035-in.-wall lnconel tube formed into a seesaw<br />

test capsule to which were brazed several nickel<br />

fins of <strong>the</strong> dish type. An excessive amount of<br />

brazing alloy was used, and <strong>the</strong> brazing time was<br />

extended to 1 hr at 19OOOF to promote dilution<br />

and diffusion. The capsule was <strong>the</strong>n filled with<br />

fluorides and operated as a seesaw test for a<br />

period of 500 hr at l5OO0F prior to examination.<br />

Since<strong>the</strong> observed 1- to 2-mil attack of <strong>the</strong> internal<br />

surface was considered to be normal, a microspark<br />

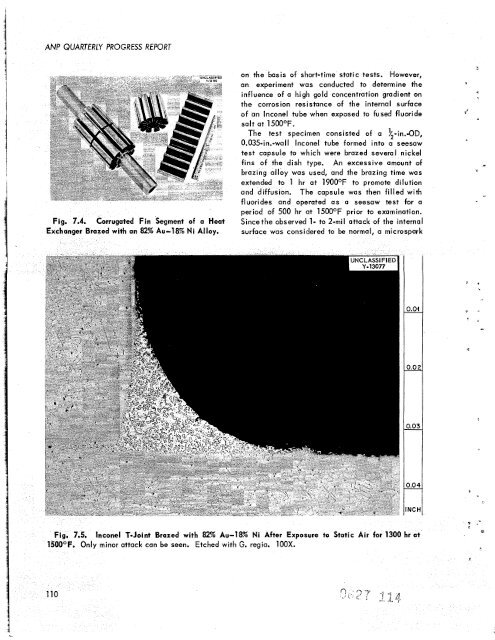

7.5. lnconel T-Joint Brazed with 82% Au-18% Ni After Exposure to Static Air for 1300 hr at<br />

15OOOF. Only minor attack can be seen. Etched with G. regia. 1OOX.<br />

F"> '7<br />

&. "! 7" t!<br />

.<br />

9 ..-

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)