ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ANP QUARTERLY PROGRESS REPORT<br />

Not ural -Gas Burner<br />

L. A. Mann<br />

Aircraft Reactor Engineering Division<br />

R. Curry<br />

Pratt & Whitney Aircraft<br />

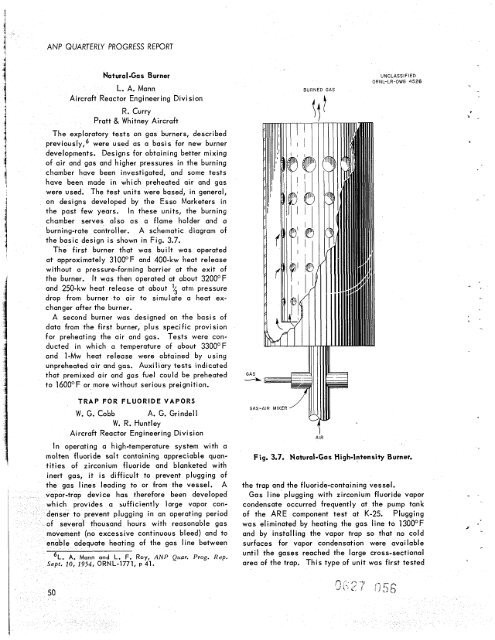

The exploratory tests on gas burners, described<br />

previously,6 were used as a basis for new burner<br />

developments. Designs for obtaining better mixing<br />

of air and gas and higher pressures in <strong>the</strong> burning<br />

chamber have been investigated, and some tests<br />

have been made in which preheated air and gas<br />

were used. The test units were based, in general,<br />

on designs developed by <strong>the</strong> Esso Marketers in<br />

<strong>the</strong> past few years. In <strong>the</strong>se units, <strong>the</strong> burning<br />

chamber serves also as a flame holder and a<br />

burning-rate controller. A schematic diagram of<br />

<strong>the</strong> basic design is shown in Fig. 3.7.<br />

The first burner that was built was operated<br />

at approximately 310OOF and 400-kw heat release<br />

without a pressure-forming barrier at <strong>the</strong> exit of<br />

<strong>the</strong> burner. It was <strong>the</strong>n operated at about 3200°F<br />

and 250-kw heat release at about $ atm pressure<br />

drop from burner to air to simulate a heat ex-<br />

changer after <strong>the</strong> burner.<br />

A second burner was designed on <strong>the</strong> basis of<br />

data from <strong>the</strong> first burner, plus specific provision<br />

for preheating <strong>the</strong> air and gas. Tests were con-<br />

ducted in which a temperature of about 330OOF<br />

and 1-Mw heat release were obtained by using<br />

unpreheated air and gas. Auxiliary tests indicated<br />

that premixed air and gas fuel could be preheated<br />

to 160OOF or more without serious preignition.<br />

TRAP FOR FLUORIDE VAPORS<br />

W. G. Cobb A. G. Grindell<br />

W. R. Huntley<br />

Aircraft Reactor Engineering Division<br />

In operating a high-temperature system with a<br />

molten fluoride salt containing appreciable quan-<br />

tities of zirconium fluoride and blanketed with<br />

inert gas, it is difficult to prevent plugging of<br />

<strong>the</strong> gas lines leading to or from <strong>the</strong> vessel. A<br />

vapor-trap device has <strong>the</strong>refore been developed<br />

which provides a sufficiently large vapor con-<br />

denser to prevent plugging in an operating period<br />

of several thousand hours with reasonable gas<br />

movement (no excessive continuous bleed) and to<br />

enable adequate heating of <strong>the</strong> gas line between<br />

'I-. A. Mann and L. F. Roy, ANP Quar. Prog. Rep.<br />

Sept. 10, 1954, <strong>ORNL</strong>-1771, p 41.<br />

50<br />

GAS<br />

---%<br />

GAS.<br />

BURNED GAS<br />

It<br />

UNCLASSIFIED<br />

<strong>ORNL</strong>-LR-DWG 4526<br />

Fig. 3.7. Natural-Gas High-Intensity Burner.<br />

<strong>the</strong> trap and <strong>the</strong> fluoride-containing vessel.<br />

Gas line plugging with zirconium fluoride vapor<br />

condensate occurred frequently at <strong>the</strong> pump tank<br />

of <strong>the</strong> ARE component test at K-25. Plugging<br />

was eliminated by heating <strong>the</strong> gas line to 130OOF<br />

and by installing <strong>the</strong> vapor trap so that no cold<br />

surfaces for vapor condensation were avai table<br />

until <strong>the</strong> gases reached <strong>the</strong> large cross-sectional<br />

area of <strong>the</strong> trap. This type of unit was first tested

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)