ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

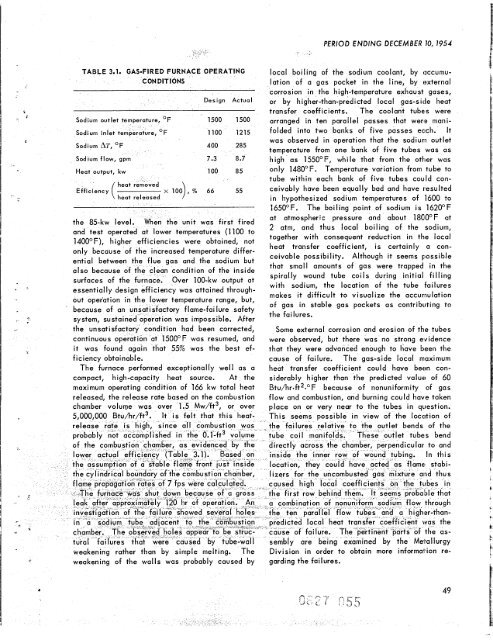

TABLE 3.1. GAS-FIRED FURNACE OPERATING<br />

CON DIT IONS<br />

Design Actual<br />

Sodium outlet 1500 1500<br />

Sodium inlet te 1100 1215<br />

400 285<br />

Sodium flow, gprn 7.3 8.7<br />

Heat output, kw 100 85<br />

Efficiency<br />

heat removed<br />

x 100). %<br />

heat released<br />

66 55<br />

and test operated at lowe<br />

1400"F), higher efficiencies were obtained, not<br />

only because of <strong>the</strong> increased temperature differ-<br />

ential between <strong>the</strong> flue gas and <strong>the</strong> sodium but<br />

also because of th condition of <strong>the</strong> inside<br />

surfaces of <strong>the</strong> fu Over 100-kw output at<br />

essentially design efficiency was attained through-<br />

perature range, but,<br />

because of an flame-fai lure safety<br />

was impossible. After<br />

ad been corrected,<br />

continuous operation at 1500OF was resumed, and<br />

it was found again that 55% was <strong>the</strong> best ef-<br />

ficiency obtainable.<br />

The furnace performed exceptionally well as a<br />

compact, high-capacity heat source. At <strong>the</strong><br />

maximum operating condition of 166 kw total heat<br />

released, <strong>the</strong> release rate based on <strong>the</strong> combustion<br />

chamber volume was over 1.5 Mw/ft3, or over<br />

5,000,000 Btu/hr/ft3. It is felt that this heat-<br />

weakening ra<strong>the</strong>r than by simple melting. The<br />

weakening of <strong>the</strong> walls was probably caused by<br />

PERlOD ENDlNG DECEMBER 70, 7954<br />

local boiling of <strong>the</strong> sodium coolant, by ~iccumu-<br />

lation of a gas pocket in <strong>the</strong> line, by external<br />

corrosion in <strong>the</strong> high-temperature exhaust gases,<br />

or by higher-than-predicted local gas-side heat<br />

transfer coefficients. The coolant tubes were<br />

arranged in ten parallel passes that werle mani-<br />

folded into two banks of five passes each. It<br />

was observed in operation that <strong>the</strong> sodium outlet<br />

temperature from one bank of five tubes was as<br />

high as 155OoF, while that from <strong>the</strong> o<strong>the</strong>r was<br />

only 1480°F. Temperature variation from tube to<br />

tube within each bank of five tubes could con-<br />

ceivably have been equally bad and have resulted<br />

in hypo<strong>the</strong>sized sodium temperatures of 1600 to<br />

165OOF. The boiling point of sodium is 1620°F<br />

at atmospheric pressure and about 1800°F at<br />

2 atm, and thus local boiling of <strong>the</strong> sodium,<br />

toge<strong>the</strong>r with consequent reduction in <strong>the</strong> local<br />

heat transfer coefficient, is certainly a con-<br />

ceivable possibility. Although it seems possible<br />

that small amounts of gas were trapped in <strong>the</strong><br />

spirally wound tube coils during initial filling<br />

with sodium, <strong>the</strong> location of <strong>the</strong> tube failures<br />

makes it difficult to visualize <strong>the</strong> accunwlation<br />

of gas in stable gas pockets as contributing to<br />

<strong>the</strong> failures.<br />

Some external corrosion and erosion of <strong>the</strong> tubes<br />

were observed, but <strong>the</strong>re was no strong evidence<br />

that <strong>the</strong>y were advanced enough to have been <strong>the</strong><br />

cause of failure. The gas-side local maximum<br />

heat transfer coefficient could have been con-<br />

siderably higher than <strong>the</strong> predicted value! of 60<br />

5tu/hr.ft2."F because of nonuniformity of gas<br />

flow and combustion, and burning could have taken<br />

place on or very near to <strong>the</strong> tubes in question.<br />

This seems Dossible in view of <strong>the</strong> location of<br />

t bends of <strong>the</strong><br />

let tubes bend<br />

endicular to and<br />

Division in order to obtain more information re-<br />

garding <strong>the</strong> failures.<br />

d 49

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)