ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP QUARTERLY PROGRESS REPORT<br />

fabricability of <strong>the</strong> cast alloy is associated with<br />

a second phase which persists after long-time heat<br />

treatments at 21OOOF.<br />

New Alloys<br />

H. lnouye J. H. Coobs<br />

Metallurgy Division<br />

Several new alloys are being studied in an attempt<br />

to find an alloy that is superior to Hastelloy B,<br />

l and efforts are being made to improve <strong>the</strong> existing<br />

ys. Preliminary results of experiments<br />

~<br />

I<br />

1<br />

arious compositions are presented<br />

Hastelloy B Plus 0.03% Cerium. A 3-lb vacuum<br />

melt was rolled at 21OO0F, and <strong>the</strong>re was con-<br />

siderably less cracking than would have been<br />

found with Hastelloy B. Numerous small defects<br />

ere present, however, that may be eliminated by<br />

increasing <strong>the</strong> cerium content of he alloy.<br />

ybdenum-Columbium-Nickel Alloy. A 20%<br />

Cb-75% Ni alloy could be cold rolled from<br />

<strong>the</strong> cast structure to sheet. The structure is twophased<br />

at 1500OF and single-phased at a solution<br />

annealing temperature of 195OOF. The tensile<br />

strength of <strong>the</strong> alloy at 1500°F is 36,800 psi<br />

(elongation 3.5%). A creep test at a temperature<br />

of 1500OF and a stress of 8000 psi is in progress.<br />

Molybdenum-AluminumNickel Alloy. A 20%<br />

Mo-2% AI-78% Ni alloy could be rolled at room<br />

temperature from <strong>the</strong> cast condition. At 1500OF<br />

<strong>the</strong> tensile strength was 43,500 psi with an elongation<br />

of 5%.<br />

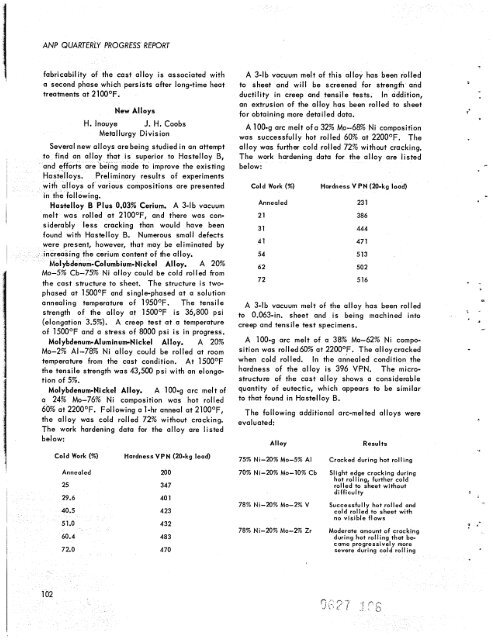

Molybdenum-Nickel Alloy. A 100-g arc melt of<br />

a 24% Mo-76% Ni composition was hot rolled<br />

60% at 220OOF. Following a 1-hr anneal at 21OO0F,<br />

<strong>the</strong> alloy was cold rolled 72% without cracking.<br />

The work hardening data for <strong>the</strong> alloy are listed<br />

Cold Work (%) HardnessVPN (20-kg load)<br />

, Annealed<br />

200<br />

25<br />

347<br />

29.6 40 1<br />

423<br />

60.4<br />

72.0<br />

432<br />

483<br />

470<br />

A 3-lb vacuum melt of this alloy has been rolled<br />

to sheet and will be screened for strength and<br />

ductility in creep and tensile tests. In addition,<br />

an extrusion of <strong>the</strong> alloy has been rolled to sheet<br />

for obtaining more detailed data.<br />

A 100-9 arc melt ofa 32% Mo-68% Ni composition<br />

was successfully hot rolled 60% at 22OOOF. The<br />

alloy was fur<strong>the</strong>r cold rolled 72% without cracking.<br />

The work hardening data for <strong>the</strong> alloy are listed<br />

below:<br />

Cold Work (%) Hardness V PN (20-kg load)<br />

Annealed 23 1<br />

21<br />

386<br />

31<br />

444<br />

41 47 1<br />

54<br />

513<br />

62<br />

502<br />

72<br />

516<br />

A 3-lb vacuum melt of <strong>the</strong> alloy has been rolled<br />

to 0.063-in. sheet and is being machined into<br />

creep and tensile test specimens.<br />

A 100-9 arc melt of a 38% M0-62% Ni compo-<br />

sition was rolled60% at 2200OF. The alloycracked<br />

when cold rolled. In <strong>the</strong> annealed condition <strong>the</strong><br />

hardness of <strong>the</strong> alloy is 396 VPN. The micro-<br />

structure of <strong>the</strong> cast alloy shows a considerable<br />

quantity of eutectic, which appears to be similar<br />

to that found in Hastelloy B.<br />

The following additional arc-melted alloys were<br />

evaluated:<br />

Alloy Results<br />

75% Ni-20% Mo-5% AI Cracked during hot rolling<br />

70% Ni-20% Mo-10% Cb Slight edge cracking during<br />

hot rolling, fur<strong>the</strong>r cold<br />

rolled to sheet without<br />

difficulty<br />

78% Ni-20% Mo-2% V Successfully hot rolled and<br />

cold rolled to sheet with<br />

no visible flaws<br />

78% Ni-20% Mo-2% Zr Moderate amount of cracking<br />

during hot rolling that be-<br />

came progressively more<br />

severe during cold rolling<br />

P<br />

4

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)