ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ANP QUARTERLY PROGRESS REPORT<br />

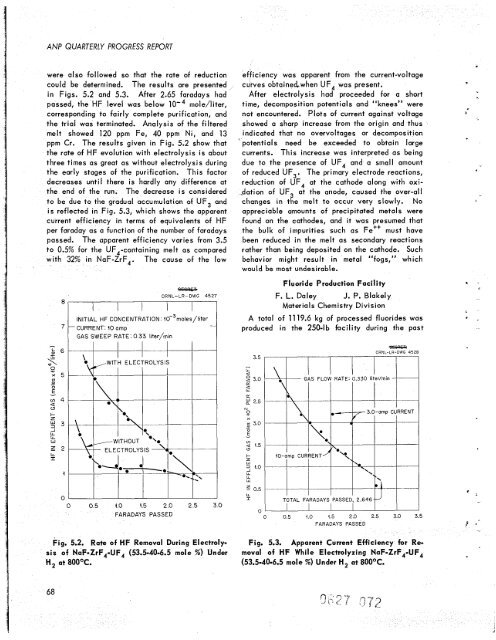

were also followed so that <strong>the</strong> rate of reduction<br />

could be determined. The results are presented<br />

in Figs. 5.2 and 5.3. After 2.65 faradays had<br />

passed, <strong>the</strong> HF level was below lo', mole/liter,<br />

corresponding to fairly complete purification, and<br />

<strong>the</strong> trial was terminated. Analysis of <strong>the</strong> filtered<br />

melt showed 120 ppm Fe, 40 ppm Ni, and 13<br />

ppm Cr. The results given in Fig. 5.2 show that<br />

<strong>the</strong> rate of HF evolution with electrolysis is about<br />

three times as great as without electrolysis during<br />

<strong>the</strong> early stages of <strong>the</strong> purification. This factor<br />

decreases unti I <strong>the</strong>re is hardly any difference at<br />

<strong>the</strong> end of <strong>the</strong> run. The decrease is considered<br />

to be due to <strong>the</strong> gradual accumulation of UF, and<br />

is reflected in Fig. 5.3, which shows <strong>the</strong> apparent<br />

current efficiency in terms of equivalents of HF<br />

per faraday as a function of <strong>the</strong> number of faradays<br />

passed. The apparent efficiency varies from 3.5<br />

to 0.5% for <strong>the</strong> UF4-containing melt as compared<br />

with 32% in NaF-ZrF,. The cause<br />

-<br />

of <strong>the</strong> low<br />

<strong>ORNL</strong>-LR-DWG 4527<br />

1<br />

k 6<br />

5<br />

2<br />

-<br />

x 5<br />

u)<br />

-<br />

m 4<br />

a<br />

(3<br />

c<br />

z<br />

Y 3<br />

_J<br />

LL<br />

LL<br />

W<br />

E 2<br />

LL<br />

I<br />

4<br />

GAS SWEEP RATE: o 33 \iter/min<br />

0<br />

0 0 5 10 15 2.0 25 30<br />

FARADAYS PASSED<br />

Fig. 5.2. Rate of HF Removal During Electroly-<br />

sis of NaF-ZrF,-UF, (53.5-40-6.5 mole X ) Under<br />

H, at 800'C.<br />

68<br />

efficiency was apparent from <strong>the</strong> current-voltage<br />

curves obtainedwhen UF, was present.<br />

After electrolysis had proceeded for a short<br />

time, decomposition potentials and "knees" were<br />

not encountered. Plots of current against voltage<br />

showed a sharp increase from <strong>the</strong> origin and thus<br />

indicated that no overvoltages or decomposition<br />

potentials need be exceeded to obtain large<br />

currents. This increase was interpreted as being<br />

due to <strong>the</strong> presence of UF, and a small amount<br />

of reduced UF,. The primary electrode reactions,<br />

reduction of UF, at <strong>the</strong> cathode along with oxi-<br />

.dation of UF, at <strong>the</strong> anode, caused <strong>the</strong> over-all<br />

changes in <strong>the</strong> melt to occur very slowly. No<br />

appreciable amounts of precipitated metals were<br />

found on <strong>the</strong> cathodes, and it was presumed that<br />

<strong>the</strong> bulk of impurities such as Fett must have<br />

been reduced in <strong>the</strong> melt as secondary reactions<br />

ra<strong>the</strong>r than being deposited on <strong>the</strong> cathode. Such<br />

behavior might result in metal "fogs," which<br />

would be most undesirable.<br />

Fluoride Production Facility ..<br />

F. L. Daley J. P. Blakely<br />

Mater ials Chemistry Division<br />

A total of 1119.6 kg of processed fluorides was<br />

produced in <strong>the</strong> 250-lb facility during <strong>the</strong> past<br />

* ,<br />

I<br />

><br />

3.5<br />

$ 3.0<br />

LT<br />

2<br />

E<br />

2.5<br />

N<br />

0<br />

x<br />

0 3.0<br />

-<br />

0<br />

E<br />

:<br />

a<br />

b-<br />

z<br />

W<br />

;<br />

LL<br />

U<br />

W<br />

U<br />

r<br />

1.5<br />

1.0<br />

0.5<br />

0<br />

TOTAL FARADAYS PASSED, 2.646<br />

esBE&l<br />

<strong>ORNL</strong>-LR-OWG 4528<br />

0 0.5 4.0 4.5 2.0 2.5 3.0 3.5<br />

FARADAYS PASSED f -<br />

Fig. 5.3. Apparent Current Efficiency for Re-<br />

moval of HF While Electrolyzing NaF-ZrF4-UF,<br />

(53.5-40-6.5 mole %) Under H, at 800%<br />

J

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)