ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP QUARTERLY PROGRESS REPORT<br />

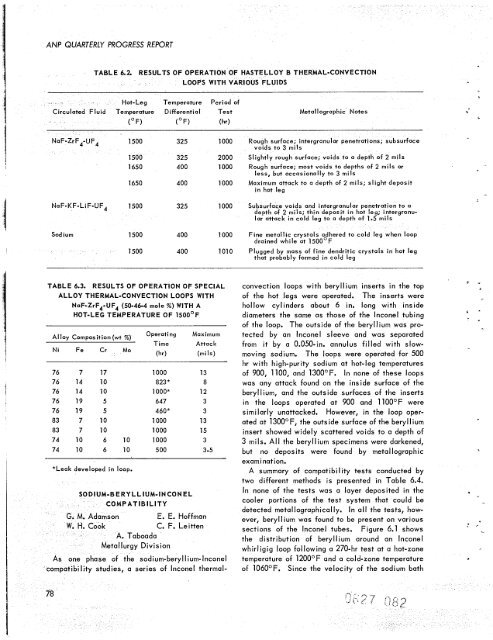

TABLE 6.2 RESULTS OF OPERATION OF HASTELLOY B THERMAL-CONVECTION<br />

LOOPS WITH VARIOUS FLUIDS<br />

Hot-Leg Temperature Period of<br />

Metallographic Notes<br />

NaF-ZrF4-UF4 1500 325 1000 Rough surface; intergranular penetrations; subsurface<br />

voids to 3 mils<br />

1500 325 2000 Slightly rough surface; voids to a depth of 2 mils<br />

1650 400 1000 Rough surface; most voids to depths of 2 mils or<br />

less, but occasionally to 3 mils<br />

1650 400 1000 Maximum attack to a depth of 2 mils; slight deposit<br />

in hot leg<br />

NaF-K F-L i F-UF4 1500 325 1000 Subsurface voids and intergranular penetration to a<br />

depth of 2 mils; thin deposit in hot leg; intergronu-<br />

lor attack in cold leg to a depth of 1.5 mils<br />

Sad ium 1500 400 1000 Fine metallic crystals<br />

drained while at 150OoF<br />

1500 400 1010 Plugged by mass of fine dendritic crystals in hot leg<br />

that probably formed in cold leg<br />

TABLE 6.3. RESULTS OF OPERATION OF SPECIAL<br />

ALLOY THERMAL-CONVECTION LOOPS WITH<br />

NaF-ZrF4-UF4 (50-46-4 mole %) WITH A<br />

HOT-LEG TEMPERATURE OF 1500°F<br />

AI ~ oy Composition (wt X)<br />

Ni Fe Cr Mo<br />

76 7 17<br />

76 14 10<br />

76 14 10<br />

76 19 5<br />

76 19 5<br />

83 7 10<br />

83 7 10<br />

74 10 6 10<br />

74 10 6 10<br />

*Leak developed in loop.<br />

Operating<br />

Time Attack<br />

(hr) (mils)<br />

1000<br />

823*<br />

1 ooo*<br />

647<br />

460*<br />

1000<br />

1000<br />

1000<br />

500<br />

13<br />

8<br />

12<br />

3<br />

3<br />

13<br />

15<br />

3<br />

3.5<br />

SODIUM-B ERYLLIUM-INCON EL<br />

COMP AT IB I Ll TY<br />

E. E. Hoffman<br />

C. F. Leitten<br />

Metallurgy Division<br />

As one phase of <strong>the</strong> sodium-beryllium-Inconel<br />

compatibility studies, a series of lnconel <strong>the</strong>rmal-<br />

* *<br />

convection loops with beryllium inserts in <strong>the</strong> top<br />

of <strong>the</strong> hot legs were operated. The inserts were -<br />

hollow cylinders about 6 in. long with inside .-<br />

diameters <strong>the</strong> same as those of <strong>the</strong> lnconel tubing<br />

of <strong>the</strong> loop. The outside of <strong>the</strong> beryllium was pro- I<br />

tected by an lnconel sleeve and was separated<br />

from it by a 0.050-in. annulus filled with slowmoving<br />

sodium. The loops were operated for 500<br />

hr with h igh-pur ity sod i um at hot- leg temperatures<br />

of 900, 1100, and 13OOOF. In none of <strong>the</strong>se loops<br />

was any attack found on <strong>the</strong> inside surface of <strong>the</strong><br />

beryllium, and <strong>the</strong> outside surfaces of <strong>the</strong> inserts<br />

in <strong>the</strong> loops operated at 900 and llOO°F were<br />

similarly unattacked. However, in <strong>the</strong> loop operated<br />

at 13OO0F, <strong>the</strong> outside surface of <strong>the</strong> beryllium<br />

insert showed widely scattered voids to a depth of<br />

3 mils. All <strong>the</strong> beryllium specimens were darkened,<br />

but no deposits were found by metallographic<br />

exam i nation.<br />

A summary of compatibility tests conducted by<br />

two different methods is presented in Table 6.4.<br />

In none of <strong>the</strong> tests was a layer deposited in <strong>the</strong><br />

cooler portions of <strong>the</strong> test system that could be<br />

-<br />

detected metallographically. In all <strong>the</strong> tests, however,<br />

beryllium was found to be present on various<br />

:,<br />

sections of <strong>the</strong> lnconel tubes. Figure 6.1 shows<br />

<strong>the</strong> distribution of beryllium around an lnconel<br />

whirligig loop following a 270-hr test at a hot-zone<br />

temperature of 120OOF and a cold-zone temperature<br />

of 106OOF. Since <strong>the</strong> velocity of <strong>the</strong> sodium bath

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)