ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

a<br />

*<br />

in this apparatus was 10 fps, <strong>the</strong> bath temperature<br />

was practically iso<strong>the</strong>rmal, The temperatures given<br />

are <strong>the</strong> outside tube wall temperatures. The be-<br />

ryllium distribution shown appears to be temperature<br />

dependent; however, in o<strong>the</strong>r dynamic tests, this<br />

was not so obvious. The outside and inside sur-<br />

faces of a beryllium insert from <strong>the</strong> hot leg of an<br />

lnconel <strong>the</strong>rmal-convection loop are shown in Fig.<br />

6.2. As in nearly all <strong>the</strong> o<strong>the</strong>r compatibility tests,<br />

Test<br />

PERIOD ENDING DECEMBER 70,7954<br />

<strong>the</strong> heaviest attack was on <strong>the</strong> outside surface of<br />

<strong>the</strong> insert. The attack was due to dissimilar metal<br />

mass transfer between <strong>the</strong> beryllium and <strong>the</strong> lnconel<br />

sleeve which surrounded it, The result clf direct<br />

contact between lnconel and beryllium in a system<br />

containing sodium at elevated temperatures may be<br />

seen in Fig. 6.3. The Be-Ni intermetallic layer<br />

which formed was approximately 20 mils thick and<br />

was extremely hard and brittle, Tests are piresently<br />

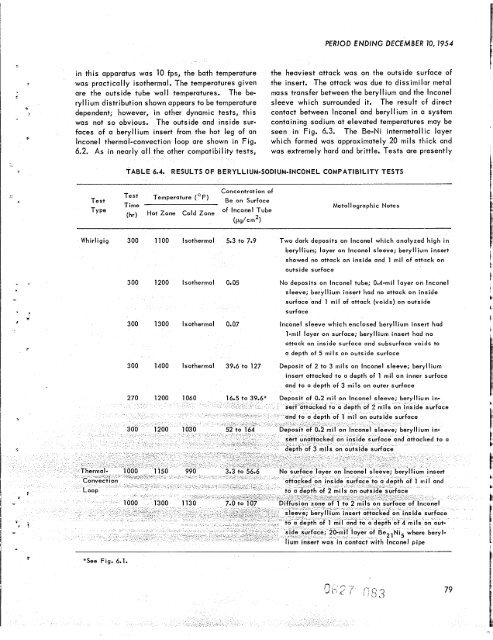

TABLE 6.4. RESULTS OF BERYLLIUM-SODIUM-INCONEL COMPATIBILITY TESTS<br />

Concentration of<br />

Test<br />

Time<br />

Temperature (OF) Be on<br />

Tube<br />

(pg/cm2)<br />

Type (hr) Hot Zone Cold Zone Of lnconel<br />

Metal I ographi c Notes<br />

Whirligig 300 1100 Iso<strong>the</strong>rmal 5.3 to 7.9 Two dark deposits on lnconel which onalyzed high in<br />

beryllium; layer on lnconel sleeve; beryllium insert<br />

showed no attack on inside and 1 mil of attack on<br />

outside surface<br />

*See Fig. 6.1.<br />

300 1200 Iso<strong>the</strong>rmal 0.05 No deposits on lnconel tube; 0.4-mil layer on lnconel<br />

sleeve; beryllium insert had no attock on inside<br />

surface and 1 mil of attack (voids) on outside<br />

surface<br />

300 1300 Iso<strong>the</strong>rmal 0.07 lnconel sleeve which enclosed beryllium insert had<br />

1-mil layer on surfoce; beryllium insert hod no<br />

attack on inside surface and subsurface voids to<br />

a depth of 5 mils on outside surfoce<br />

300 1400 Iso<strong>the</strong>rmal 39.6 to 127 Deposit of 2 to 3 mils on lnconel sleeve; beryllium<br />

insert ottqcked to a depth of 1 mil on inner surfoce<br />

and to a depth of 3 mils on outer surfoce<br />

79<br />

t<br />

L<br />

r<br />

I<br />

L<br />

k<br />

t<br />

t<br />

c<br />

b

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)