ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

ANP QUARTERLY PROGRESS REPORT<br />

kw at a pressure drop of 50 Ib, 10 kw at 5 Ib,<br />

d 5 kw at approximately 1 Ib. Since <strong>the</strong> maximum<br />

at removal required is expected to be no more<br />

an 10 kw, <strong>the</strong> heat exchanger appears to be more<br />

CREEP AND STRESS-CORROSION TESTS<br />

avis J. C. Wilson<br />

N. E. Hinkle<br />

J. C. Zukas<br />

Solid State Division<br />

stress-corrosion apparatus described pre-<br />

s has been bench tested. The design ap-<br />

o be sound, and <strong>the</strong>refore a new rig is being<br />

canned for insertion in <strong>the</strong> LITR. Temperature<br />

control to within 52°F at 150OOF has been achieved<br />

by using a Speedomax air-controller to drive <strong>the</strong><br />

that supplies <strong>the</strong> furnace power. Operation<br />

riods of 500 hr has shown that, if sodium<br />

distills out of <strong>the</strong> hot zone of <strong>the</strong> furnace, so little<br />

sodium is lost that its effectiveness as a heat<br />

'W. W. Davis et al., ANP Qwr. Prog. Rep. Sept. 10,<br />

1954, <strong>ORNL</strong>-1771, p 142.<br />

.t<br />

transfer agent is not diminished. Welding of some t<br />

joints has been poor, and <strong>the</strong>refore Dy-Chek is<br />

being used in <strong>the</strong> inspection of all new welds.<br />

The LITR Experiment Review Committee has ape<br />

proved <strong>the</strong> apparatus for irradiat<br />

necessary safety circuit for <strong>the</strong> LITR has been<br />

completed.<br />

In <strong>the</strong> bench tests <strong>the</strong> outside of t<br />

was in air,ra<strong>the</strong>r than in sodium as it would be in<br />

<strong>the</strong> in-pile apparatus. The tests were for periods<br />

of 432 and 866 hr at 15OOOF and a stress of 1500<br />

psi. The specimen exposed for <strong>the</strong> longer time<br />

showed roughly twice as many voids per unit area<br />

on <strong>the</strong> sides of <strong>the</strong> tube stressed in tension and<br />

compression as <strong>the</strong>re were on <strong>the</strong> sides at zero<br />

stress. The maximum depth of voids was about<br />

0.001 in. It was also noticed that <strong>the</strong> etching (or<br />

perhaps staining) characteristics of <strong>the</strong> salt-metal<br />

interface were not <strong>the</strong> same for <strong>the</strong> stressed and<br />

unstressed regions when etched in aqua regia.<br />

The reproducibility of <strong>the</strong> creep data obtained was<br />

not good, and <strong>the</strong>refore <strong>the</strong> specimen shape has<br />

been modified in order to concentrate more of <strong>the</strong> * .<br />

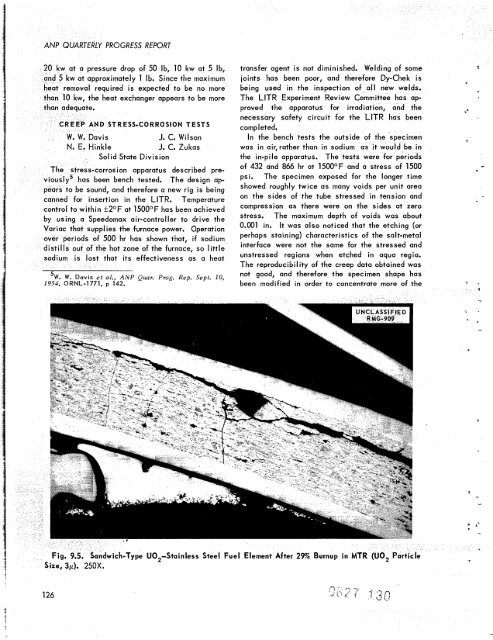

Fig. 9.5. Sandwich-Type U0,-Stainless Steel Fuel Element After 29% Burnup in MTR<br />

S Nize, 3p). 250X.<br />

126<br />

.<br />

1<br />

1

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)