ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP QUARTERLY PROGRESS REPORT<br />

-<br />

N<br />

-.<br />

14<br />

13<br />

12<br />

11<br />

IO<br />

$ 9<br />

0<br />

10<br />

‘ 0 8 -<br />

W<br />

m<br />

4 7<br />

W<br />

(L<br />

0<br />

z 6<br />

I-<br />

I<br />

(.!I<br />

f 5<br />

s<br />

4<br />

3<br />

2<br />

1<br />

UNCLASSIFIED<br />

<strong>ORNL</strong>-LR-DWG 4426<br />

0 0 20 40 60 80 100 I20 140 160 180 200<br />

ELAPSED TIME (hr)<br />

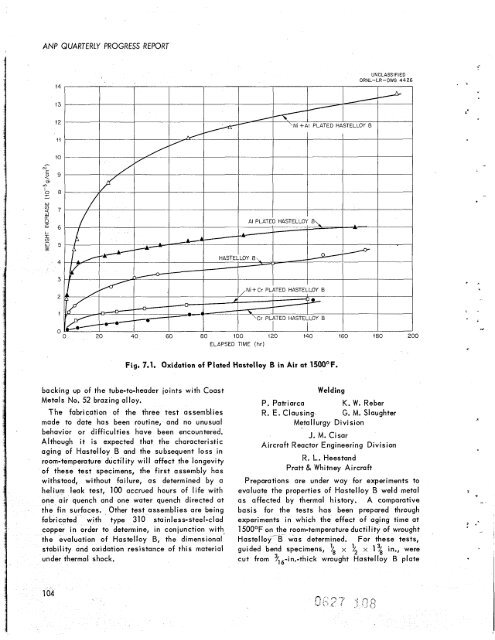

Fig. 7.1. Oxidation of Plated Hastelloy B in Air at 1500OF.<br />

backing up of <strong>the</strong> tube-to-header joints with Coast<br />

Welding<br />

Metals No. 52 brazing alloy.<br />

The fabrication of <strong>the</strong> three test assemblies<br />

P. Patriarca<br />

R. E. Clausing<br />

K. W. Reber<br />

G. M. Slaughter<br />

made to date has been routine, and no unusual Metallurgy Division<br />

behavior or difficulties have been encountered.<br />

Although it is expected that <strong>the</strong> characteristic<br />

aging of Hastelloy B and <strong>the</strong> subsequent loss in<br />

room-temperature ductility will affect <strong>the</strong> longevity<br />

of <strong>the</strong>se test specimens, <strong>the</strong> first assembly has<br />

J. M. Cisar<br />

Aircraft R eactor Engineering Division<br />

R. L. Heestand<br />

Pratt & Whitney Aircraft<br />

withstood, without failure, as determined by a Preparations are under way for experiments to<br />

helium leak test, 100 accrued hours of life with evaluate <strong>the</strong> properties of Hastelloy B weld metal<br />

one air quench and one water quench directed at as affected by <strong>the</strong>rmal history. A comparative<br />

<strong>the</strong> fin surfaces. O<strong>the</strong>r test assemblies are being basis for <strong>the</strong> tests has been prepared through<br />

fabricated with type 310 stainless-steel-clad experiments in which <strong>the</strong> effect of aging time at<br />

copper in order to determine, in conjunction with 15OOOF on <strong>the</strong> room-temperature ductility of wrought<br />

<strong>the</strong> evaluation of Hastelloy B, <strong>the</strong> dimensional<br />

stability and oxidation resistance of this material<br />

Hastelloy- B was determined. For <strong>the</strong>se tests,<br />

guided bend specimens, x y2 x 1% in., were<br />

under <strong>the</strong>rmal shock. cut from 3/,6-in.-thick wrought Hastelloy B plate<br />

. .<br />

. -<br />

4

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)