ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

ORNL-1816 - the Molten Salt Energy Technologies Web Site

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

ANP QUARTERLY PROGRESS REPORT<br />

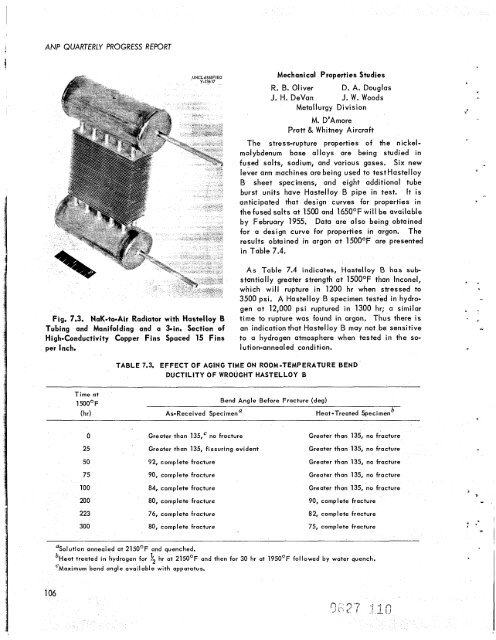

Fig. 7.3. NaK-to-Air Radiator with Hastelloy 6<br />

Tubing and Manifolding and a Sin. Section of<br />

High-Conductivity Copper Fins Spaced 15 Fins<br />

per Inch.<br />

106<br />

Mechanical Properties Studies<br />

R. B. Oliver D. A. Douglas<br />

J. H. DeVan J. W. Woods<br />

Metallurgy Division<br />

M. D'Amore<br />

Pratt & Whitney Aircraft<br />

The stress-rupture properties of <strong>the</strong> nickel-<br />

molybdenum base alloys are being studied in<br />

fused salts, sodium, and various gases. Six new<br />

lever arm machines are being used to testHastelloy<br />

B sheet specimens, and eight additional tube<br />

burst units have Hastelloy B pipe in test. It is<br />

anticipated that design curves for properties in<br />

<strong>the</strong> fused salts at 1500 and 165OOF will be available<br />

by February 1955. Data are also being obtained<br />

for a design curve for properties in argon. The<br />

results obtained in argon at 15OOOF are presented<br />

in Table 7.4.<br />

As Table 7.4 indicates, Hastelloy B has sub-<br />

stantially greater strength at 15OOOF than Inconel,<br />

which will rupture in 1200 hr when stressed to<br />

3500 psi. A Hastelloy B specimen tested in hydro-<br />

gen at 12,000 psi ruptured in 1300 hr; a similar<br />

time to rupture was found in argon. Thus <strong>the</strong>re is<br />

an indication that Hastelloy B may not be sensitive<br />

to a hydrogen atmosphere when tested in <strong>the</strong> so-<br />

l ution-annealed condition.<br />

TABLE 7.3. EFFECT OF AGING TIME ON ROOM-TEMPERATURE BEND<br />

DUCTILITY OF WROUGHT HASTELLOY B<br />

Time at<br />

Bend Angle Before Fracture (deg)<br />

150OoF<br />

b<br />

(hr) As-Received Specimen ' Heat-Treated Specimen<br />

0<br />

25<br />

50<br />

75<br />

100<br />

200<br />

223<br />

300<br />

Greater than 135,c no fracture<br />

Greater than 135, fissuring evideni<br />

92, complete fracture<br />

90, complete fracture<br />

84, complete fracture<br />

80, complete fracture<br />

76, complete fracture<br />

80, complete fracture<br />

'Solution annealed at 215OOF and quenched.<br />

1<br />

Greater than 135, no fracture<br />

Greater than 135, no fracture<br />

Greater than 135, no fracture<br />

Greater than 135, no fracture<br />

Greater than 135, no fracture<br />

90, complete fracture<br />

82, complete fracture<br />

75, complete fracture<br />

bHeat treated in hydrogen for /2 hr at 215OoF and <strong>the</strong>n for 30 hr at 195OOF followed by water quench.<br />

CMaximum bend angle available with apparatus.<br />

i -<br />

*<br />

a<br />

.<br />

-

![Review of Molten Salt Reactor Physics Calculations [Disc 2]](https://img.yumpu.com/21979492/1/190x247/review-of-molten-salt-reactor-physics-calculations-disc-2.jpg?quality=85)