Atlas Copco - Annual Report 1999

Atlas Copco - Annual Report 1999

Atlas Copco - Annual Report 1999

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

CONSTRUCTION AND MINING TECHNIQUE<br />

CONSTRUCTION AND MINING TECHNIQUE<br />

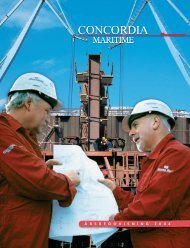

Customer and supplier join<br />

forces in product development<br />

Close cooperation with customers is essential for success in developing state-of-<br />

the-art rock drilling equipment. A basic requirement for a new product is that it<br />

improves customers’ operations. <strong>Atlas</strong> <strong>Copco</strong>’s Rock Drilling Equipment division<br />

continuously interacts with its customers to achieve better results in ever-<br />

changing rock conditions.<br />

One example of how supplier-customer<br />

partnerships<br />

can successfully overcome<br />

formidable obstacles is<br />

apparent at the Zinkgruvan<br />

mine, located near the northern<br />

tip of Vättern, Sweden’s<br />

second largest lake. <strong>Atlas</strong><br />

<strong>Copco</strong> and the mine have<br />

cooperated on the development of drilling rigs and components<br />

for nearly 20 years. The benefits for both parties are significant.<br />

By participating in the development and testing of new products,<br />

the client gain quicker access to more efficient products that are<br />

adapted to their requirements and reduce their cost per ton of<br />

52 ATLAS COPCO <strong>1999</strong><br />

ore. <strong>Atlas</strong> <strong>Copco</strong>, in turn, benefits from<br />

shorter time-to-market and products that<br />

better match market demands.<br />

The partnership is now contributing to<br />

a program designed to improve production<br />

drilling at Zinkgruvan. The changes<br />

involve closer cooperation between the<br />

four major underground mining areas and<br />

improvements in mining methods. An<br />

<strong>Atlas</strong> <strong>Copco</strong>-Zinkgruvan interactive project<br />

group was formed to evaluate investment in a new production<br />

rig and to define its specifications. Zinkgruvan set several criteria:<br />

accuracy of less than one degree in positioning the feed; high<br />

availability from reduced downtime between varied drilling tasks;<br />

fixed alternatives in the control system for different applications<br />

to reduce downtime and drill-steel consumption.<br />

The project group opted for the updated Simba rig, which<br />

drills straighter and longer holes. Following changes at the<br />

mine, it will have a higher degree of utilization. The new rig will<br />

give Zinkgruvan the flexibility and accuracy needed to handle<br />

shifts in mining conditions and any alterations in methods they<br />

may wish to make.