Atlas Copco - Annual Report 1999

Atlas Copco - Annual Report 1999

Atlas Copco - Annual Report 1999

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

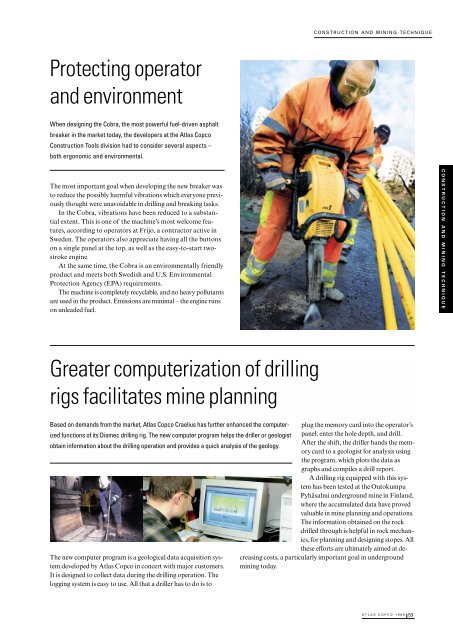

Protecting operator<br />

and environment<br />

When designing the Cobra, the most powerful fuel-driven asphalt<br />

breaker in the market today, the developers at the <strong>Atlas</strong> <strong>Copco</strong><br />

Construction Tools division had to consider several aspects –<br />

both ergonomic and environmental.<br />

The most important goal when developing the new breaker was<br />

to reduce the possibly harmful vibrations which everyone previously<br />

thought were unavoidable in drilling and breaking tasks.<br />

In the Cobra, vibrations have been reduced to a substantial<br />

extent. This is one of the machine’s most welcome features,<br />

according to operators at Frijo, a contractor active in<br />

Sweden. The operators also appreciate having all the buttons<br />

on a single panel at the top, as well as the easy-to-start twostroke<br />

engine.<br />

At the same time, the Cobra is an environmentally friendly<br />

product and meets both Swedish and U.S. Environmental<br />

Protection Agency (EPA) requirements.<br />

The machine is completely recyclable, and no heavy pollutants<br />

are used in the product. Emissions are minimal – the engine runs<br />

on unleaded fuel.<br />

Greater computerization of drilling<br />

rigs facilitates mine planning<br />

Based on demands from the market, <strong>Atlas</strong> <strong>Copco</strong> Craelius has further enhanced the computerized<br />

functions of its Diamec drilling rig. The new computer program helps the driller or geologist<br />

obtain information about the drilling operation and provides a quick analysis of the geology.<br />

The new computer program is a geological data acquisition system<br />

developed by <strong>Atlas</strong> <strong>Copco</strong> in concert with major customers.<br />

It is designed to collect data during the drilling operation. The<br />

logging system is easy to use. All that a driller has to do is to<br />

CONSTRUCTION AND MINING TECHNIQUE<br />

plug the memory card into the operator’s<br />

panel, enter the hole depth, and drill.<br />

After the shift, the driller hands the memory<br />

card to a geologist for analysis using<br />

the program, which plots the data as<br />

graphs and compiles a drill report.<br />

A drilling rig equipped with this system<br />

has been tested at the Outokumpu<br />

Pyhäsalmi underground mine in Finland,<br />

where the accumulated data have proved<br />

valuable in mine planning and operations.<br />

The information obtained on the rock<br />

drilled through is helpful in rock mechanics,<br />

for planning and designing stopes. All<br />

these efforts are ultimately aimed at decreasing<br />

costs, a particularly important goal in underground<br />

mining today.<br />

ATLAS COPCO <strong>1999</strong> 53<br />

CONSTRUCTION AND MINING TECHNIQUE