dry anaerobic digestion of municipal solid waste and digestate ...

dry anaerobic digestion of municipal solid waste and digestate ...

dry anaerobic digestion of municipal solid waste and digestate ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

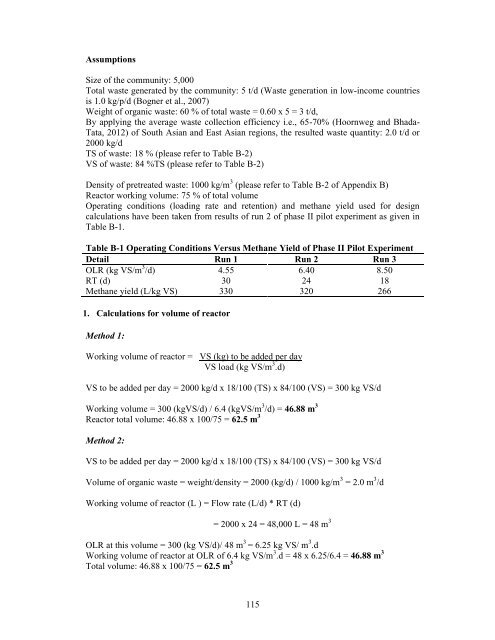

Assumptions<br />

Size <strong>of</strong> the community: 5,000<br />

Total <strong>waste</strong> generated by the community: 5 t/d (Waste generation in low-income countries<br />

is 1.0 kg/p/d (Bogner et al., 2007)<br />

Weight <strong>of</strong> organic <strong>waste</strong>: 60 % <strong>of</strong> total <strong>waste</strong> = 0.60 x 5 = 3 t/d,<br />

By applying the average <strong>waste</strong> collection efficiency i.e., 65-70% (Hoornweg <strong>and</strong> Bhada -<br />

Tata, 2012) <strong>of</strong> South Asian <strong>and</strong> East Asian regions, the resulted <strong>waste</strong> quantity: 2.0 t/d or<br />

2000 kg/d<br />

TS <strong>of</strong> <strong>waste</strong>: 18 % (please refer to Table B-2)<br />

VS <strong>of</strong> <strong>waste</strong>: 84 %TS (please refer to Table B-2)<br />

Density <strong>of</strong> pretreated <strong>waste</strong>: 1000 kg/m 3 (please refer to Table B-2 <strong>of</strong> Appendix B)<br />

Reactor working volume: 75 % <strong>of</strong> total volume<br />

Operating conditions (loading rate <strong>and</strong> retention) <strong>and</strong> methane yield used for design<br />

calculations have been taken from results <strong>of</strong> run 2 <strong>of</strong> phase II pilot experiment as given in<br />

Table B-1.<br />

Table B-1 Operating Conditions Versus Methane Yield <strong>of</strong> Phase II Pilot Experiment<br />

Detail Run 1 Run 2 Run 3<br />

OLR (kg VS/m 3 /d) 4.55 6.40 8.50<br />

RT (d) 30 24 18<br />

Methane yield (L/kg VS) 330 320 266<br />

1. Calculations for volume <strong>of</strong> reactor<br />

Method 1:<br />

Working volume <strong>of</strong> reactor = VS (kg) to be added per day<br />

VS load (kg VS/m 3 .d)<br />

VS to be added per day = 2000 kg/d x 18/100 (TS) x 84/100 (VS) = 300 kg VS/d<br />

Working volume = 300 (kgVS/d) / 6.4 (kgVS/m 3 /d) = 46.88 m 3<br />

Reactor total volume: 46.88 x 100/75 = 62.5 m 3<br />

Method 2:<br />

VS to be added per day = 2000 kg/d x 18/100 (TS) x 84/100 (VS) = 300 kg VS/d<br />

Volume <strong>of</strong> organic <strong>waste</strong> = weight/density = 2000 (kg/d) / 1000 kg/m 3 = 2.0 m 3 /d<br />

Working volume <strong>of</strong> reactor (L ) = Flow rate (L/d) * RT (d)<br />

= 2000 x 24 = 48,000 L = 48 m 3<br />

OLR at this volume = 300 (kg VS/d)/ 48 m 3 = 6.25 kg VS/ m 3 .d<br />

Working volume <strong>of</strong> reactor at OLR <strong>of</strong> 6.4 kg VS/m 3 .d = 48 x 6.25/6.4 = 46.88 m 3<br />

Total volume: 46.88 x 100/75 = 62.5 m 3<br />

115