dry anaerobic digestion of municipal solid waste and digestate ...

dry anaerobic digestion of municipal solid waste and digestate ...

dry anaerobic digestion of municipal solid waste and digestate ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong>digestion</strong>, etc. Moreover, mixing <strong>of</strong> different kinds <strong>of</strong> <strong>waste</strong> will also be done to adjust C/N<br />

ratio.<br />

- The OFMSW received from the community will be consisting <strong>of</strong> a mixture <strong>of</strong> food <strong>waste</strong>,<br />

vegetable <strong>waste</strong> <strong>and</strong> fruit <strong>waste</strong>, with C/N ratio in the range <strong>of</strong> 18-25. Based on the<br />

findings <strong>of</strong> this thesis, the feedstock C/N ratio 32 is helpful to mitigate ammonia<br />

accumulation problem in <strong>dry</strong> AD. Thus feedstock C/N ratio should be adjusted by mixing<br />

it with high C/N ratio material (e.g. <strong>waste</strong> paper, saw dust, etc.).<br />

- In our pilot experiments, various feed mixtures were prepared <strong>and</strong> used to achieve the<br />

above objective, the details <strong>of</strong> which are given in Appendix B, Table B-2. The<br />

recommended material from our experimental results is that 5-7% <strong>of</strong> total <strong>waste</strong> should<br />

consist <strong>of</strong> <strong>waste</strong> paper. However, the composition may be varied depending on the C/N<br />

ratio <strong>of</strong> feedstock received from the community. Layout <strong>of</strong> the decentralized <strong>digestion</strong><br />

system to be established for treating OFMSW <strong>of</strong> the community has been shown in Figure<br />

4.20. For this purpose, a shredder-cum -mixer will be used as shown in the Figure.<br />

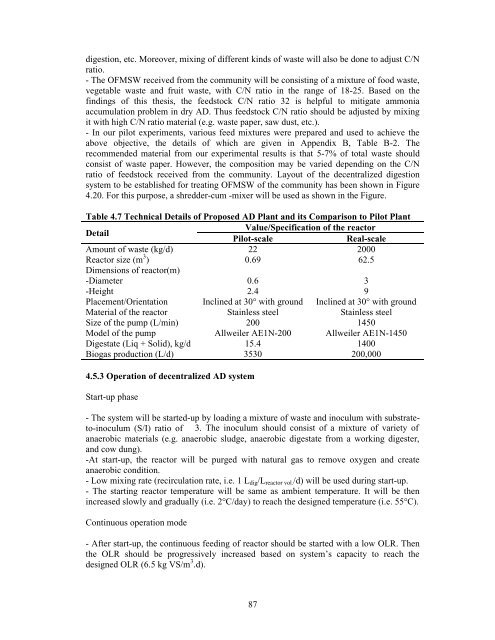

Table 4.7 Technical Details <strong>of</strong> Proposed AD Plant <strong>and</strong> its Comparison to Pilot Plant<br />

Detail<br />

Value/Specification <strong>of</strong> the reactor<br />

Pilot-scale Real-scale<br />

Amount <strong>of</strong> <strong>waste</strong> (kg/d) 22 2000<br />

Reactor size (m 3 ) 0.69 62.5<br />

Dimensions <strong>of</strong> reactor(m)<br />

-Diameter<br />

0.6<br />

3<br />

-Height<br />

2.4<br />

9<br />

Placement/Orientation Inclined at 30° with ground Inclined at 30° with ground<br />

Material <strong>of</strong> the reactor Stainless steel Stainless steel<br />

Size <strong>of</strong> the pump (L/min) 200 1450<br />

Model <strong>of</strong> the pump Allweiler AE1N-200 Allweiler AE1N-1450<br />

Digestate (Liq + Solid), kg/d 15.4 1400<br />

Biogas production (L/d) 3530 200,000<br />

4.5.3 Operation <strong>of</strong> decentralized AD system<br />

Start-up phase<br />

- The system will be started-up by loading a mixture <strong>of</strong> <strong>waste</strong> <strong>and</strong> inoculum with substrateto-inoculum<br />

(S/I) ratio <strong>of</strong> ≤ 3. The inoculum should consist <strong>of</strong> a mixture <strong>of</strong> variety <strong>of</strong><br />

<strong>anaerobic</strong> materials (e.g. <strong>anaerobic</strong> sludge, <strong>anaerobic</strong> <strong>digestate</strong> from a working digester,<br />

<strong>and</strong> cow dung).<br />

-At start-up, the reactor will be purged with natural gas to remove oxygen <strong>and</strong> create<br />

<strong>anaerobic</strong> condition.<br />

- Low mixing rate (recirculation rate, i.e. 1 Ldig/Lreactor vol./d) will be used during start-up.<br />

- The starting reactor temperature will be same as ambient temperature. It will be then<br />

increased slowly <strong>and</strong> gradually (i.e. 2°C/day) to reach the designed temperature (i.e. 55°C).<br />

Continuous operation mode<br />

- After start-up, the continuous feeding <strong>of</strong> reactor should be started with a low OLR. Then<br />

the OLR should be progressively increased based on system’s capacity to reach the<br />

designed OLR (6.5 kg VS/m 3 .d).<br />

87