dry anaerobic digestion of municipal solid waste and digestate ...

dry anaerobic digestion of municipal solid waste and digestate ...

dry anaerobic digestion of municipal solid waste and digestate ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

feedstocks were sub-sampled <strong>and</strong> freeze-thawed under ambient temperature for loading<br />

into the reactor. The simulations were also characterized in different time intervals during<br />

the long time storage. The average total <strong>solid</strong> (TS), volatile <strong>solid</strong> (VS) <strong>and</strong> ca rbon (C)<br />

contents <strong>of</strong> the Feedstocks 1 & 2, <strong>and</strong> Feedstock 3 were 20.2%, 85%TS, 51.5%TS <strong>and</strong><br />

17%, 86%TS, 51%TS respectively.<br />

3.2 Experimental Set-up<br />

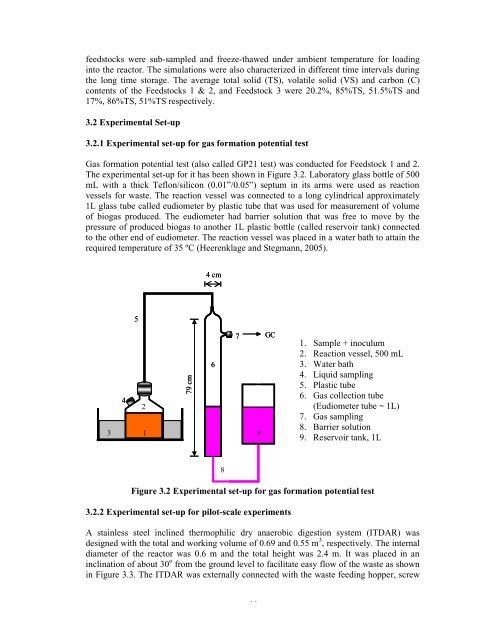

3.2.1 Experimental set-up for gas formation potential test<br />

Gas formation potential test (also called GP21 test) was conducted for Feedstock 1 <strong>and</strong> 2.<br />

The experimental set-up for it has been shown in Figure 3.2. Laboratory glass bottle <strong>of</strong> 500<br />

mL with a thick Teflon/silicon (0.01”/0.05”) septum in its arms were used as reaction<br />

vessels for <strong>waste</strong>. The reaction vessel was connected to a long cylindrical approximately<br />

1L glass tube called eudiometer by plastic tube that was used for measurement <strong>of</strong> volume<br />

<strong>of</strong> biogas produced. The eudiometer had barrier solution that was free to move by the<br />

pressure <strong>of</strong> produced biogas to another 1L plastic bottle (called reservoir tank) connected<br />

to the other end <strong>of</strong> eudiometer. The reaction vessel was placed in a water bath to attain the<br />

required temperature <strong>of</strong> 35 ºC (Heerenklage <strong>and</strong> Stegmann, 2005).<br />

3<br />

4<br />

5<br />

2<br />

1<br />

79 cm<br />

4 cm<br />

Figure 3.2 Experimental set-up for gas formation potential test<br />

3.2.2 Experimental set-up for pilot-scale experiments<br />

6<br />

8<br />

7<br />

A stainless steel inclined thermophilic <strong>dry</strong> <strong>anaerobic</strong> <strong>digestion</strong> system (ITDAR) was<br />

designed with the total <strong>and</strong> working volume <strong>of</strong> 0.69 <strong>and</strong> 0.55 m 3 , respectively. The internal<br />

diameter <strong>of</strong> the reactor was 0.6 m <strong>and</strong> the total height was 2.4 m. It was placed in an<br />

inclination <strong>of</strong> about 30 o from the ground level to facilitate easy flow <strong>of</strong> the <strong>waste</strong> as shown<br />

in Figure 3.3. The ITDAR was externally connected with the <strong>waste</strong> feeding hopper, screw<br />

46<br />

9<br />

GC<br />

1. Sample + inoculum<br />

2. Reaction vessel, 500 mL<br />

3. Water bath<br />

4. Liquid sampling<br />

5. Plastic tube<br />

6. Gas collection tube<br />

(Eudiometer tube ~ 1L)<br />

7. Gas sampling<br />

8. Barrier solution<br />

9. Reservoir tank, 1L