dry anaerobic digestion of municipal solid waste and digestate ...

dry anaerobic digestion of municipal solid waste and digestate ...

dry anaerobic digestion of municipal solid waste and digestate ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

(vertical height to deliver <strong>digestate</strong> to the reactor) for the real scale reactor is just 3 times<br />

that <strong>of</strong> pilot reactor as given in Table B-6. But, to meet the high delivery (L/min) due to<br />

huge size <strong>of</strong> real plant, much higher size (not just 3 times like head) <strong>of</strong> pump should be<br />

used.<br />

Calculations for selecting the size <strong>of</strong> pump<br />

As the same operating conditions <strong>and</strong> feed composition will be replicated, almost the same<br />

viscosity <strong>of</strong> the reactor material will achieve in real scale reactor. Also the practical flow<br />

rate <strong>of</strong> real scale pump can be calculated from pilot observation as follows:<br />

The practical flow rate <strong>of</strong> pilot pump (200 L/min) = 25 L/min<br />

If we select a pump size <strong>of</strong> 1450 L/min for the proposed real-scale reactor,<br />

Its practical flow rate will be: = 25/200 x 1450 = 181 L/min<br />

Time taken to recirculate whole reactor material for 1 time<br />

= 47000 (L)/181 (L/min)<br />

= 260 min<br />

Recirculation time required to achieve the recirculation rate <strong>of</strong> 2.5 Ldig/Lreactor vol./d<br />

= 2.5 x 260 min = 650 min<br />

Recirculation frequency: 4 times/d (in every 6 h) = 650/4 = 160 min ≈ 3 h<br />

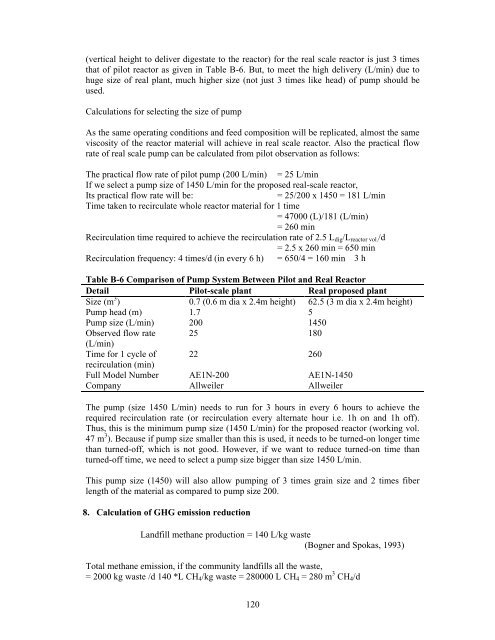

Table B-6 Comparison <strong>of</strong> Pump System Between Pilot <strong>and</strong> Real Reactor<br />

Detail Pilot-scale plant Real proposed plant<br />

Size (m 3 ) 0.7 (0.6 m dia x 2.4m height) 62.5 (3 m dia x 2.4m height)<br />

Pump head (m) 1.7 5<br />

Pump size (L/min) 200 1450<br />

Observed flow rate<br />

(L/min)<br />

25 180<br />

Time for 1 cycle <strong>of</strong> 22 260<br />

recirculation (min)<br />

Full Model Number AE1N-200 AE1N-1450<br />

Company Allweiler Allweiler<br />

The pump (size 1450 L/min) needs to run for 3 hours in every 6 hours to achieve the<br />

required recirculation rate (or recirculation every alternate hour i.e. 1h on <strong>and</strong> 1h <strong>of</strong>f).<br />

Thus, this is the minimum pump size (1450 L/min) for the proposed reactor (working vol.<br />

47 m 3 ). Because if pump size smaller than this is used, it needs to be turned-on longer time<br />

than turned-<strong>of</strong>f, which is not good. However, if we want to reduce turned-on time than<br />

turned-<strong>of</strong>f time, we need to select a pump size bigger than size 1450 L/min.<br />

This pump size (1450) will also allow p umping <strong>of</strong> 3 times grain size <strong>and</strong> 2 times fiber<br />

length <strong>of</strong> the material as compared to pump size 200.<br />

8. Calculation <strong>of</strong> GHG emission reduction<br />

L<strong>and</strong>fill methane production = 140 L/kg <strong>waste</strong><br />

(Bogner <strong>and</strong> Spokas, 1993)<br />

Total methane emission, if the community l<strong>and</strong>fills all the <strong>waste</strong>,<br />

= 2000 kg <strong>waste</strong> /d 140 *L CH4/kg <strong>waste</strong> = 280000 L CH4 = 280 m 3 CH4/d<br />

120