special - Alu-web.de

special - Alu-web.de

special - Alu-web.de

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

SPECIAL<br />

ALUMINIUM SMELTING INDUSTRY<br />

than standard grain refiners and promotes<br />

fine equiaxed structures. Its efficiency as a<br />

grain refiner is at least twice, sometimes up to<br />

thirty times higher than standard Ti Bal refiners<br />

normally used.<br />

An in<strong>de</strong>pen<strong>de</strong>nt metallographic study also<br />

shows that Optifine grain refiner has a very<br />

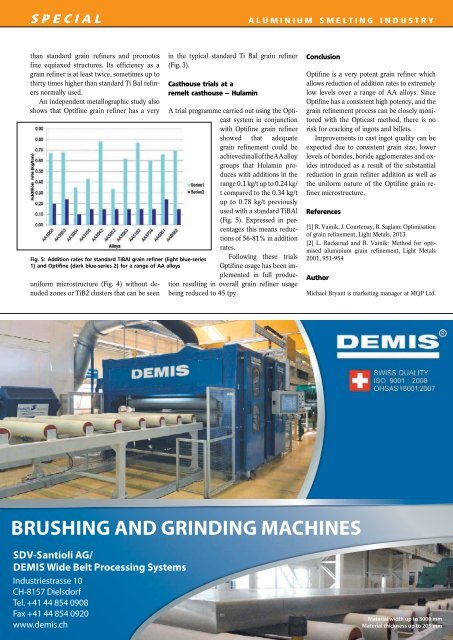

Fig. 5: Addition rates for standard TiBAl grain refiner (light blue-series<br />

1) and Optifine (dark blue-series 2) for a range of AA alloys<br />

uniform microstructure (Fig. 4) without <strong>de</strong>nu<strong>de</strong>d<br />

zones or TiB2 clusters that can be seen<br />

in the typical standard Ti Bal grain refiner<br />

(Fig. 3).<br />

Casthouse trials at a<br />

remelt casthouse – Hulamin<br />

A trial programme carried out using the Opticast<br />

system in conjunction<br />

with Optifine grain refiner<br />

showed that a<strong>de</strong>quate<br />

grain refinement could be<br />

achieved in all of the AA alloy<br />

groups that Hulamin produces<br />

with additions in the<br />

range 0.1 kg/t up to 0.24 kg/<br />

t compared to the 0.34 kg/t<br />

up to 0.78 kg/t previously<br />

used with a standard TiBAl<br />

(Fig. 5). Expressed in percentages<br />

this means reductions<br />

of 56-81% in addition<br />

rates.<br />

Following these trials<br />

Optifine usage has been implemented<br />

in full production<br />

resulting in overall grain refiner usage<br />

being reduced to 45 tpy.<br />

Conclusion<br />

Optifine is a very potent grain refiner which<br />

allows reduction of addition rates to extremely<br />

low levels over a range of AA alloys. Since<br />

Optifine has a consistent high potency, and the<br />

grain refinement process can be closely monitored<br />

with the Opticast method, there is no<br />

risk for cracking of ingots and billets.<br />

Improvements in cast ingot quality can be<br />

expected due to consistent grain size, lower<br />

levels of bori<strong>de</strong>s, bori<strong>de</strong> agglomerates and oxi<strong>de</strong>s<br />

introduced as a result of the substantial<br />

reduction in grain refiner addition as well as<br />

the uniform nature of the Optifine grain refiner<br />

microstructure.<br />

References<br />

[1] R. Vainik, J. Courtenay, B. Saglam: Optimisation<br />

of grain refinement, Light Metals, 2013<br />

[2] L. Backerud and R. Vainik: Method for optimised<br />

aluminium grain refinement, Light Metals<br />

2001, 951-954<br />

Author<br />

Michael Bryant is marketing manager at MQP Ltd.<br />

BRUSHING AND GRINDING MACHINES<br />

SDV-Santioli AG/<br />

DEMIS Wi<strong>de</strong> Belt Processing Systems<br />

Industriestrasse 10<br />

CH-8157 Dielsdorf<br />

Tel. +41 44 854 0908<br />

Fax +41 44 854 0920<br />

www.<strong>de</strong>mis.ch<br />

Material width up to 3000 mm<br />

Material thickness up to 205 mm