special - ALUMINIUM-Nachrichten – ALU-WEB.DE

special - ALUMINIUM-Nachrichten – ALU-WEB.DE

special - ALUMINIUM-Nachrichten – ALU-WEB.DE

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong><strong>ALU</strong>MINIUM</strong> SMELTING INDUSTRY<br />

KPI<br />

Unit<br />

Dec 2010<br />

to<br />

July 2011<br />

Aug 2011<br />

to<br />

Feb 2012<br />

Mar 2012<br />

to<br />

Sept 2012<br />

1 Oct 2012<br />

to<br />

21 Nov 2012<br />

Amperage kA 419.6 430.2 439.7 440.1<br />

Current efficiency % 95.1 94.9 94.5 94.9<br />

Metal production kg/pot-day 3214 3291 3345 3366<br />

Volts per cell V 4.22* 4.22** 4.24*** 4.24***<br />

DC specific energy kWh/kg Al 13.22* 13.25** 13.37*** 13.37***<br />

Net carbon consumption kg/kg Al 407 412 404 0.398<br />

Fe % 0.040 0.039 0.043 0.036<br />

Si % 0.028 0.029 0.028 0.026<br />

AE frequency AE/pot-day 0.191 0.085 0.071 0.046<br />

AE duration s 9.6 10.3 10.1 10.3<br />

PFC emissions,<br />

CO 2 equivalent****<br />

kg/t Al 33 16 13 9<br />

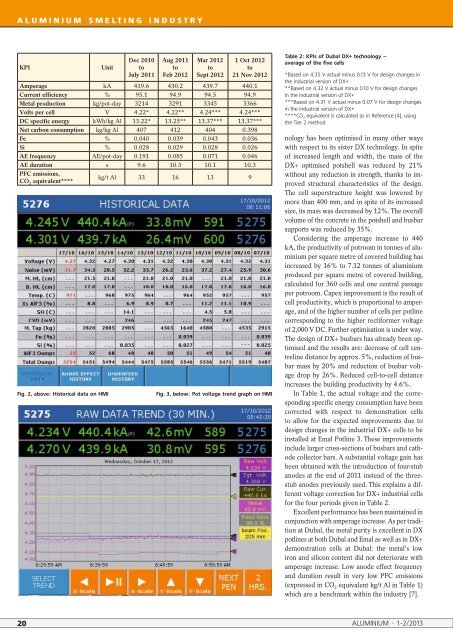

Fig. 2, above: Historical data on HMI<br />

Fig. 3, below: Pot voltage trend graph on HMI<br />

Table 2: KPIs of Dubal DX+ technology <strong>–</strong><br />

average of the five cells<br />

*Based on 4.35 V actual minus 0.13 V for design changes in<br />

the industrial version of DX+<br />

**Based on 4.32 V actual minus 0.10 V for design changes<br />

in the industrial version of DX+<br />

***Based on 4.31 V actual minus 0.07 V for design changes<br />

in the industrial version of DX+<br />

****CO 2 equivalent is calculated as in Reference [4], using<br />

the Tier 2 method<br />

nology has been optimised in many other ways<br />

with respect to its sister DX technology. In spite<br />

of increased length and width, the mass of the<br />

DX+ optimised potshell was reduced by 21%<br />

without any reduction in strength, thanks to improved<br />

structural characteristics of the design.<br />

The cell superstructure height was lowered by<br />

more than 400 mm, and in spite of its increased<br />

size, its mass was decreased by 12%. The overall<br />

volume of the concrete in the potshell and busbar<br />

supports was reduced by 35%.<br />

Considering the amperage increase to 440<br />

kA, the productivity of potroom in tonnes of aluminium<br />

per square metre of covered building has<br />

increased by 16% to 7.12 tonnes of aluminium<br />

produced per square metre of covered building,<br />

calculated for 360 cells and one central passage<br />

per potroom. Capex improvement is the result of<br />

cell productivity, which is proportional to amperage,<br />

and of the higher number of cells per potline<br />

corresponding to the higher rectiformer voltage<br />

of 2,000 V DC. Further optimisation is under way.<br />

The design of DX+ busbars has already been optimised<br />

and the results are: decrease of cell centreline<br />

distance by approx. 5%, reduction of busbar<br />

mass by 20% and reduction of busbar voltage<br />

drop by 26%. Reduced cell-to-cell distance<br />

increases the building productivity by 4.6%.<br />

In Table 1, the actual voltage and the corresponding<br />

specific energy consumption have been<br />

corrected with respect to demonstration cells<br />

to allow for the expected improvements due to<br />

design changes in the industrial DX+ cells to be<br />

installed at Emal Potline 3. These improvements<br />

include larger cross-sections of busbars and cathode<br />

collector bars. A substantial voltage gain has<br />

been obtained with the introduction of four-stub<br />

anodes at the end of 2011 instead of the threestub<br />

anodes previously used. This explains a different<br />

voltage correction for DX+ industrial cells<br />

for the four periods given in Table 2.<br />

Excellent performance has been maintained in<br />

conjunction with amperage increase. As per tradition<br />

at Dubal, the metal purity is excellent in DX<br />

potlines at both Dubal and Emal as well as in DX+<br />

demonstration cells at Dubal: the metal’s low<br />

iron and silicon content did not deteriorate with<br />

amperage increase. Low anode effect frequency<br />

and duration result in very low PFC emissions<br />

(expressed in CO 2 equivalent kg/t Al in Table 1)<br />

which are a benchmark within the industry [7].<br />

20 <strong><strong>ALU</strong>MINIUM</strong> · 1-2/2013