special - ALUMINIUM-Nachrichten – ALU-WEB.DE

special - ALUMINIUM-Nachrichten – ALU-WEB.DE

special - ALUMINIUM-Nachrichten – ALU-WEB.DE

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

<strong><strong>ALU</strong>MINIUM</strong> SMELTING INDUSTRY<br />

The ‘AP Technology’ smelter of the future<br />

The economical, energy efficient and environmentally safe solution for primary aluminium production<br />

S. Fraysse, J.-M. Jolas, F. Charmier and O. Martin, Rio Tinto Alcan<br />

An efficient smelter solution is made up<br />

of many technological buildings blocks.<br />

The degree of interaction between the<br />

blocks is quite high and can be complex.<br />

Rio Tinto Alcan has not only continuously<br />

developed and optimised these blocks;<br />

over the years, it has also developed a<br />

global approach to its smelter solution.<br />

The global approach, code named<br />

Global Smelter Design (GSD), is used to<br />

design the smelter of the future, building<br />

global and coherent solutions based on a<br />

functional and cross-cutting view of the<br />

plant. The approach has been made even<br />

more relevant by new available technologies<br />

and products in fields as varied as<br />

automation, robotics, data processing,<br />

environmental expertise, innovative civil<br />

works and new materials.<br />

Global smelter design builds upon the<br />

first-in-class AP Technology processes<br />

and in particular, reduction cells to optimise<br />

global development of the smelter<br />

solution.<br />

use the same generic cell equipment:<br />

• AP6X cell, the benchmark of cell<br />

productivity<br />

• APXe, operating at low energy<br />

consumption and the benchmark<br />

environmental performance.<br />

These two versions will make it possible to deliver<br />

optimal solutions for greenfield projects<br />

starting in the next few years.<br />

The first APXe cell was started in December<br />

2010 and has already delivered very<br />

promising results: after less than one year of<br />

operation, the 12.3 kWh/kg target has been<br />

achieved with very low fluoride emission and<br />

at particularly low gas suction rates [1].<br />

More ambitious targets are already planned<br />

for the coming months. Some of the innovative<br />

solutions developed on the APXe cell can also<br />

be deployed in existing aluminium smelters<br />

in order to reduce their energy consumption<br />

and environmental footprint.<br />

An industrial demonstration of AP6X<br />

Platform <strong>–</strong> Jonquiere, Quebec: The Rio Tinto<br />

board of directors approved the AP60 Phase<br />

Reduction cells to support the<br />

existing assets optimisation<br />

and the smelters of the future<br />

The team which has supplied technologies to<br />

a large number of aluminium smelter projects<br />

over the last 40 years has had a unique opportunity<br />

to develop and industrialise the best<br />

cells to meet the greatest constraints and challenges.<br />

The technical challenge of low energy: After<br />

125 years of operation, Hall-Héroult process<br />

cell productivity has improved dramatically<br />

through the development of high-amperage<br />

cells. However, improvement in energy efficiency<br />

levelled off after the seventies. In the<br />

coming decades, the challenge of massive demand<br />

for aluminium in an energy-constrained<br />

future calls for the development of low-energy<br />

cell designs.<br />

With the different AP cell platforms, Rio<br />

Tinto Alcan proposes a comprehensive suite<br />

of solutions able to take up this challenge and<br />

to adapt to changing market trends. This offer<br />

is based on two platforms, AP6X-APXe and<br />

AP4X.<br />

AP6X <strong>–</strong> APXe platform: Rio Tinto Alcan<br />

has developed two new cell technologies that<br />

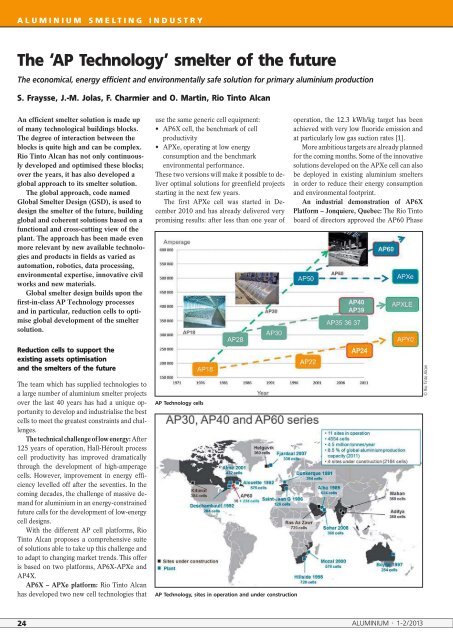

AP Technology cells<br />

AP Technology, sites in operation and under construction<br />

© Rio Tinto Alcan<br />

24 <strong><strong>ALU</strong>MINIUM</strong> · 1-2/2013