Service Manual, General Motors 4.3L Engine (TP ... - Kohler Power

Service Manual, General Motors 4.3L Engine (TP ... - Kohler Power

Service Manual, General Motors 4.3L Engine (TP ... - Kohler Power

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

6-104 Marine/Industrial <strong>4.3L</strong> <strong>Engine</strong><br />

156173<br />

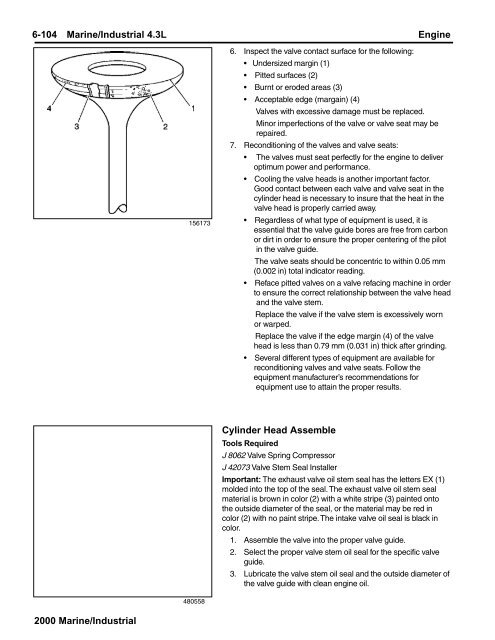

6. Inspect the valve contact surface for the following:<br />

• Undersized margin (1)<br />

• Pitted surfaces (2)<br />

• Burnt or eroded areas (3)<br />

• Acceptable edge (margain) (4)<br />

Valves with excessive damage must be replaced.<br />

Minor imperfections of the valve or valve seat may be<br />

repaired.<br />

7. Reconditioning of the valves and valve seats:<br />

• The valves must seat perfectly for the engine to deliver<br />

optimum power and performance.<br />

• Cooling the valve heads is another important factor.<br />

Good contact between each valve and valve seat in the<br />

cylinder head is necessary to insure that the heat in the<br />

valve head is properly carried away.<br />

• Regardless of what type of equipment is used, it is<br />

essential that the valve guide bores are free from carbon<br />

or dirt in order to ensure the proper centering of the pilot<br />

in the valve guide.<br />

The valve seats should be concentric to within 0.05 mm<br />

(0.002 in) total indicator reading.<br />

• Reface pitted valves on a valve refacing machine in order<br />

to ensure the correct relationship between the valve head<br />

and the valve stem.<br />

Replace the valve if the valve stem is excessively worn<br />

or warped.<br />

Replace the valve if the edge margin (4) of the valve<br />

head is less than 0.79 mm (0.031 in) thick after grinding.<br />

• Several different types of equipment are available for<br />

reconditioning valves and valve seats. Follow the<br />

equipment manufacturer’s recommendations for<br />

equipment use to attain the proper results.<br />

Cylinder Head Assemble<br />

Tools Required<br />

J 8062 Valve Spring Compressor<br />

J 42073 Valve Stem Seal Installer<br />

Important: The exhaust valve oil stem seal has the letters EX (1)<br />

molded into the top of the seal. The exhaust valve oil stem seal<br />

material is brown in color (2) with a white stripe (3) painted onto<br />

the outside diameter of the seal, or the material may be red in<br />

color (2) with no paint stripe. The intake valve oil seal is black in<br />

color.<br />

1. Assemble the valve into the proper valve guide.<br />

2. Select the proper valve stem oil seal for the specific valve<br />

guide.<br />

3. Lubricate the valve stem oil seal and the outside diameter of<br />

the valve guide with clean engine oil.<br />

480558<br />

2000 Marine/Industrial