Service Manual, General Motors 4.3L Engine (TP ... - Kohler Power

Service Manual, General Motors 4.3L Engine (TP ... - Kohler Power

Service Manual, General Motors 4.3L Engine (TP ... - Kohler Power

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

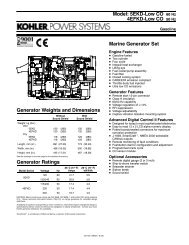

6-66 Marine/Industrial <strong>4.3L</strong> <strong>Engine</strong><br />

334378<br />

<strong>Engine</strong> Block Clean and Inspect<br />

Tools Required<br />

J 8087 Cylinder Bore Gauge<br />

Caution: Refer to Safety Glasses Caution in Cautions and<br />

Notices.<br />

1. Clean all the remaining sealing or gasket material from the<br />

sealing surfaces.<br />

2. Clean the engine block with cleaning solvent.<br />

3. Flush the engine block with clean water or steam.<br />

4. Clean the cylinder bores.<br />

5. Clean the oil galleries and the oil passages.<br />

6. Clean the scale and the deposits from the coolant<br />

passages.<br />

Notice: Clean all debris, dirt and coolant from the engine block<br />

cylinder head bolt holes. Failure to remove all foreign material may<br />

result in damaged threads, improperly tightened fasteners or<br />

damage to the components.<br />

7. Clean the engine block cylinder head bolt holes.<br />

8. After cleaning the engine block, spray or wipe the cylinder<br />

bores and the machined surfaces with clean engine oil.<br />

9. Inspect the following areas:<br />

• Coolant jackets (1) for cracks<br />

• Cylinder bores (2) for scratches or gouging<br />

• Valve lifter bores (3) for excessive scoring or wear<br />

• Threaded holes (4) for damage<br />

• Crankshaft bearing webs (5) for cracks<br />

• Crankshaft bearing caps (6) and the crankshaft bearing<br />

bores (7) for damage<br />

- The crankshaft bearing bores should be round and<br />

uniform when measuring the inside diameter (ID).<br />

- The surface where the crankshaft bearings contact the<br />

crankshaft bearing bore should be smooth.<br />

- If a crankshaft bearing cap is damaged and requires<br />

replacement, replace the crankshaft bearing cap first,<br />

then rebore the engine block crankshaft bearing bores<br />

and check for proper alignment. Finally, check the<br />

crankshaft fro the proper clearances.<br />

• <strong>Engine</strong> block core hole plug bores (8) for damage<br />

• <strong>Engine</strong> block (9) fro cracks or damage<br />

• <strong>Engine</strong> mount bosses (10) for damage<br />

2000 Marine/Industrial