- Page 1 and 2:

TABLE OF CONTENTS EXECUTIVE SUMMARY

- Page 3 and 4:

TABLE DES MATIÈRES NOTE DE SYNTHÈ

- Page 5 and 6:

PART II. TECHNICAL ANALYSIS AND SYS

- Page 7 and 8:

4. IMPACT OF P&T ON RISK ASSESSMENT

- Page 9 and 10:

Figure II.31 Evolution of the expec

- Page 11 and 12:

Part II: Technical analysis and sys

- Page 13 and 14:

There are several scenarios which c

- Page 15 and 16:

eactor concepts are still in the co

- Page 17 and 18:

intermediate storage management, th

- Page 20 and 21:

1. INTRODUCTION 1.1 Involvement of

- Page 22:

and natural decay play an important

- Page 25 and 26:

Figure I.2 A schematic diagram of b

- Page 27 and 28:

Instead of recycling, one could ado

- Page 29 and 30:

to address there is the separation

- Page 31 and 32:

improvement of the biological shiel

- Page 33 and 34:

Figure I.3 A schematic diagram of t

- Page 35 and 36:

Figure1.5 A notional materials flow

- Page 37 and 38:

A few specific regulatory and safet

- Page 39 and 40:

• irradiation of FR-fuel in Fast

- Page 41 and 42:

dispersion in the geosphere or bios

- Page 43 and 44:

In the meantime the burn-up of spen

- Page 45 and 46:

Any reprocessing campaign of spent

- Page 48 and 49:

4. CRITICAL EVALUATION • P&T may

- Page 50:

5. GENERAL CONCLUSIONS • Fundamen

- Page 54 and 55:

NOTE DE SYNTHÈSE ET PORTÉE DU RAP

- Page 56 and 57:

Présentation générale Cette part

- Page 58 and 59:

courts. L’application de cette te

- Page 60 and 61:

éalisable, à condition d’augmen

- Page 62:

PREMIÈRE PARTIE : PRÉSENTATION G

- Page 65 and 66:

La troisième réunion internationa

- Page 67 and 68:

1.5 Objectifs du rapport Dans l’e

- Page 69 and 70:

Figure I.1 Schéma de principe du c

- Page 71 and 72:

• l ’241 Am est le précurseur

- Page 73 and 74:

plutonium et environ 2 m 3 de déch

- Page 75 and 76:

2.3 Technologie de fabrication des

- Page 77:

cadre de la coopération EFTTRA ont

- Page 80 and 81: On peut voir sur la Figure I.4 les

- Page 82 and 83: Figure I.4 Flux de matières dans u

- Page 84 and 85: À court terme, les produits de fis

- Page 86 and 87: Par conséquent, au cas où l’on

- Page 88 and 89: De nombreux laboratoires dans le mo

- Page 90 and 91: usé devrait représenter environ 3

- Page 92 and 93: le nucléide le plus gênant est le

- Page 94 and 95: transuraniens. Pour obtenir un taux

- Page 96 and 97: On peut considérer des opérations

- Page 98 and 99: devrait en principe ouvrir de nouve

- Page 101: 5. CONCLUSIONS GÉNÉRALES • La m

- Page 105: PART II: TECHNICAL ANALYSIS AND SYS

- Page 108 and 109: 1.1.1.1 Minor actinides Americium a

- Page 110 and 111: thus preventing its dispersion in t

- Page 112 and 113: By contrast, information about the

- Page 114 and 115: DIDPA [5] (see Figure II.3) process

- Page 116 and 117: The generation of secondary effluen

- Page 118 and 119: Figure II.5 TRPO process TRPO solve

- Page 120 and 121: According to Jarvinen et al. in LAN

- Page 122 and 123: curium. • Separation of americium

- Page 124 and 125: 1.1.4.4 Separation of technetium an

- Page 126 and 127: The second option is production of

- Page 128 and 129: Figure II.9 Fuel cycle actinide bur

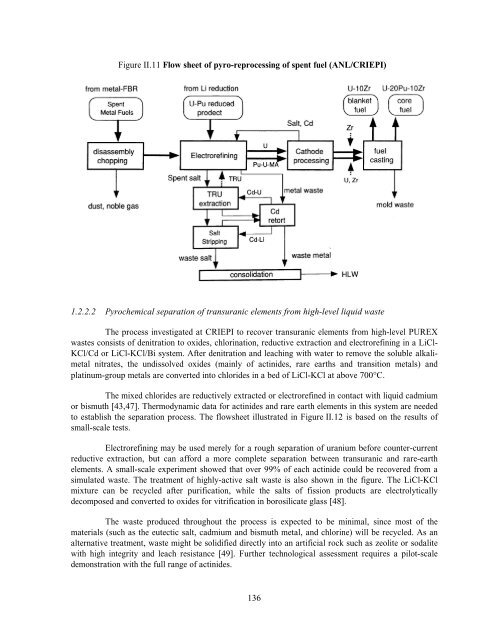

- Page 132 and 133: The metathetical reaction between L

- Page 134 and 135: This is confirmed by the radiotoxic

- Page 136 and 137: For the same burn-up as in the pure

- Page 138 and 139: planned for a burn-up range of 1.5

- Page 140 and 141: On the basis of the study, it is no

- Page 142 and 143: In a given reactor system, the diff

- Page 144 and 145: - deterioration of the effectivenes

- Page 146 and 147: Table II.5 Mass balances for homoge

- Page 148 and 149: manufacture is 2 years. 12×24 targ

- Page 150 and 151: Figure II.14 MA-loading methods in

- Page 152 and 153: Table II.7 Mass balances for homoge

- Page 154 and 155: Table II.8 Mass balances for hetero

- Page 156 and 157: Core characteristics above: The fol

- Page 158 and 159: Figure II.15 Concept of double stra

- Page 160 and 161: Figure II.16 Concept of accelerator

- Page 162 and 163: In Reference [99], the sodium coole

- Page 164 and 165: In Germany, some small activities r

- Page 166 and 167: OECD/NEA programmes The OECD/NEA Nu

- Page 168 and 169: As a part of MA nuclear data evalua

- Page 170 and 171: Table II.13 Pu and minor actinide b

- Page 172 and 173: 2.4.1.3 Transmutation in light wate

- Page 174 and 175: 3. DESCRIPTION OF CURRENT TRENDS IN

- Page 176 and 177: The SPIN programme studied various

- Page 178 and 179: • the RP1-2 scenario is compared

- Page 180 and 181:

Mass balance The MA mass balance, f

- Page 182 and 183:

4. IMPACT OF P&T ON RISK ASSESSMENT

- Page 184 and 185:

For deterministic effects, in the c

- Page 186 and 187:

• accounting for a number of safe

- Page 188 and 189:

Table II.17 Effective dose coeffici

- Page 190 and 191:

MOX fuel and recycling of recovered

- Page 192 and 193:

Figure II.22 Potential radioactivit

- Page 194 and 195:

Moreover, plutonium recycling and m

- Page 196 and 197:

Curium is assumed to be stored for

- Page 198 and 199:

Figure II.25 shows the radiotoxicit

- Page 200 and 201:

decrease is obtained in the radioto

- Page 202 and 203:

4.4 Risk and hazard assessment over

- Page 204 and 205:

4.4.2 Radiological impact of waste

- Page 206 and 207:

0.191 man-Sv/TWhe and the RFC with

- Page 208 and 209:

• conventional reprocessing does

- Page 210 and 211:

The maximum inventory of reactor co

- Page 212 and 213:

pursued. Since 137 Cs and 90 Sr are

- Page 214 and 215:

Figure II.26 Surface facilities. Ge

- Page 216 and 217:

Doses are controlled by 36 Cl up to

- Page 218 and 219:

Figure II.30 Overview of the canist

- Page 220 and 221:

surface. The reference repository i

- Page 222 and 223:

Figure II.34 Cavern-convection scen

- Page 224 and 225:

Figure II.36 Normal evolution scena

- Page 226 and 227:

considerable energy release as a re

- Page 228 and 229:

• taking into account the potenti

- Page 230 and 231:

• on the subject of transmutation

- Page 232 and 233:

[12] Arnaud-Neu, F., et al., “Cal

- Page 234 and 235:

Fuel”, Proc. Int. Conf. on Future

- Page 236 and 237:

[64] Arai, T., Suzuki, Y., Handa, M

- Page 238 and 239:

[88] Murata, H., and Mukaiyama, T.,

- Page 240 and 241:

[117] Gudowski, W., “Accelerator-

- Page 242 and 243:

[146] D’angelo, A., Marimbeau, P.

- Page 244 and 245:

[172] OECD/NEA and IAEA, Uranium: R

- Page 246:

[202] Schmidt, E., Zamorani, E., Ha