2008 Annual report - Sappi

2008 Annual report - Sappi

2008 Annual report - Sappi

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

sappi<br />

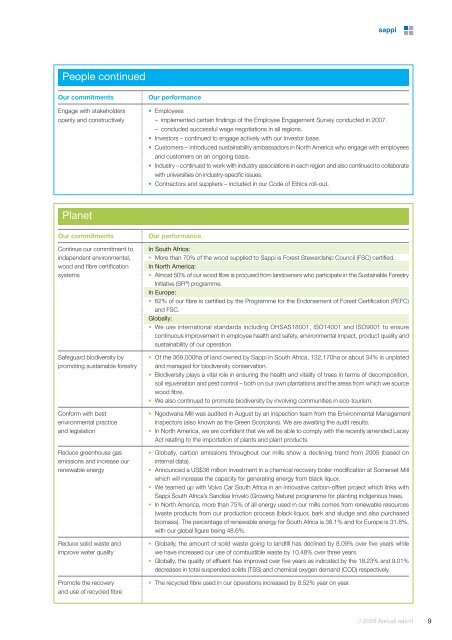

People continued<br />

Our commitments<br />

Our performance<br />

Engage with stakeholders • Employees<br />

openly and constructively – implemented certain findings of the Employee Engagement Survey conducted in 2007.<br />

– concluded successful wage negotiations in all regions.<br />

• Investors – continued to engage actively with our investor base.<br />

• Customers – introduced sustainability ambassadors in North America who engage with employees<br />

and customers on an ongoing basis.<br />

• Industry – continued to work with industry associations in each region and also continued to collaborate<br />

with universities on industry-specific issues.<br />

• Contractors and suppliers – included in our Code of Ethics roll-out.<br />

Planet<br />

Our commitments<br />

Continue our commitment to<br />

independent environmental,<br />

wood and fibre certification<br />

systems<br />

Safeguard biodiversity by<br />

promoting sustainable forestry<br />

Conform with best<br />

environmental practice<br />

and legislation<br />

Reduce greenhouse gas<br />

emissions and increase our<br />

renewable energy<br />

Reduce solid waste and<br />

improve water quality<br />

Promote the recovery<br />

and use of recycled fibre<br />

Our performance<br />

In South Africa:<br />

• More than 70% of the wood supplied to <strong>Sappi</strong> is Forest Stewardship Council (FSC) certified.<br />

In North America:<br />

• Almost 50% of our wood fibre is procured from landowners who participate in the Sustainable Forestry<br />

Initiative (SFI ® ) programme.<br />

In Europe:<br />

• 62% of our fibre is certified by the Programme for the Endorsement of Forest Certification (PEFC)<br />

and FSC.<br />

Globally:<br />

• We use international standards including OHSAS18001, ISO14001 and ISO9001 to ensure<br />

continuous improvement in employee health and safety, environmental impact, product quality and<br />

sustainability of our operation.<br />

• Of the 369,000ha of land owned by <strong>Sappi</strong> in South Africa, 132,170ha or about 34% is unplated<br />

and managed for biodiversity conservation.<br />

• Biodiversity plays a vital role in ensuring the health and vitality of trees in terms of decomposition,<br />

soil rejuvenation and pest control – both on our own plantations and the areas from which we source<br />

wood fibre.<br />

• We also continued to promote biodiversity by involving communities in eco-tourism.<br />

• Ngodwana Mill was audited in August by an inspection team from the Environmental Management<br />

Inspectors (also known as the Green Scorpions). We are awaiting the audit results.<br />

• In North America, we are confident that we will be able to comply with the recently amended Lacey<br />

Act relating to the importation of plants and plant products.<br />

• Globally, carbon emissions throughout our mills show a declining trend from 2005 (based on<br />

internal data).<br />

• Announced a US$36 million investment in a chemical recovery boiler modification at Somerset Mill<br />

which will increase the capacity for generating energy from black liquor.<br />

• We teamed up with Volvo Car South Africa in an innovative carbon-offset project which links with<br />

<strong>Sappi</strong> South Africa’s Sandisa Imvelo (Growing Nature) programme for planting indigenous trees.<br />

• In North America, more than 75% of all energy used in our mills comes from renewable resources<br />

(waste products from our production process (black liquor, bark and sludge and also purchased<br />

biomass). The percentage of renewable energy for South Africa is 38.1% and for Europe is 31.8%,<br />

with our global figure being 48.6%.<br />

• Globally, the amount of solid waste going to landfill has declined by 8.09% over five years while<br />

we have increased our use of combustible waste by 10.48% over three years.<br />

• Globally, the quality of effluent has improved over five years as indicated by the 18.23% and 9.01%<br />

decreases in total suspended solids (TSS) and chemical oxygen demand (COD) respectively.<br />

• The recycled fibre used in our operations increased by 8.52% year on year.<br />

// <strong>2008</strong> <strong>Annual</strong> <strong>report</strong><br />

9